Aerospace CNC (Computer Numeric Control) machining is a manufacturing process in which computer software is used to control the movement of machine tools. CNC machining is used to produce precise and complex parts for the aerospace industry. These parts are often made from materials such as aluminum, titanium, and various types of steel, and they may be used in the construction of aircraft, spacecraft, and other aerospace vehicles.

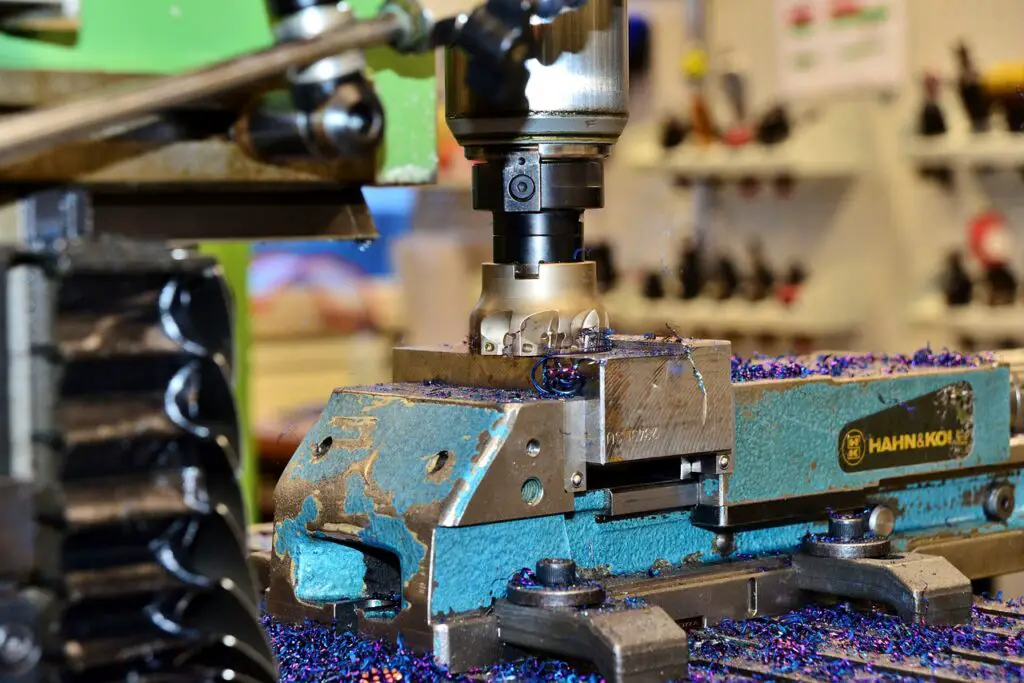

In aerospace CNC machining, a computer program is used to control the movement of the machine tools and to specify the dimensions and tolerances of the parts being produced. The program is typically created using computer-aided design (CAD) software, which allows the operator to input the desired shape and size of the part. The machine then uses a variety of tools, such as mills, lathes, and drilling machines, to cut and shape the material according to the specifications in the program.

One of the benefits of aerospace CNC machining is its ability to produce parts with a high level of precision and repeatability. The use of computer control allows for the production of parts with tight tolerances, which is important in the aerospace industry where the performance and safety of aircraft and other vehicles depend on the precise functioning of their components. Additionally, CNC machine allow for the efficient production of large quantities of parts, making it a cost-effective option for aerospace manufacturers.

CNC Machining Techniques Used in the Aerospace Industry

In order for an aviation component to be considered safe and appropriate, it must be manufactured with great accuracy and precision. With its precise tolerances and intricate pieces, CNC machining plays a significant manufacturing role in this situation. For the aerospace industry, many forms of CNC machining are utilized to enable the greatest quality of work while saving time and money. There are several CNC machining techniques that are commonly used in the aerospace industry, including:

1. 5-Axis CNC Machines

The machine is exceptionally precise since it employs 5 axes simultaneously to work (5 Axis CNC Machining). Complex aerospace parts call for specialized materials, which the 5-axis CNC machine can work with. The aerospace sector finds this machining technique to be advantageous. This manufacturing capability can produce complex products in a fraction of the time and with a much higher degree of accuracy than other CNC machinery with fewer axes.

2. AI-Assisted CNC Machinery

The CNC machining sector will benefit significantly from AI and machine learning. Both the producers’ production systems and the product quality will be improved as a result.

AI will make it so the machine will be in charge of comprehending the design patterns and responding appropriately. Manufacturers will be able to make high-quality parts with few to no mistakes thanks to it.

The use of AI and machine learning will guarantee that the parts are created with more accuracy, with a stronger focus on design, and with fewer space for error. Less wastage and lower cost per unit for the manufacturers are guaranteed.

3. 3D CNC Machining

Larger aerospace components necessitate complex operating equipment, which is why these parts are typically produced using a 3D CNC machine. This makes it possible to accomplish procedures more easily, accurately, and affordably.

Multiple components can be produced using 3D machining in a range of materials. This guarantees that components can be produced to specifications and meet standards.

4. CNC Turning

Manufacturing aeronautical parts with CNC turning enables them to work effectively together. A CNC lathe machine that spins at high speeds and removes extra material is controlled by CAD software. By enabling flawless components to function together, this technique of CNC machining improves reliability in the aerospace industry.

Benefits of Using CNC Machines in Aerospace Industry

Whether for commercial air travel, space aviation, or the defence sector, aerospace parts and structures must be taken into account. When considering aircraft, longevity and accuracy must be considered because they frequently fly for extended periods of time, even years. Each component must be made with extreme accuracy and precise engineering. When it comes to this, CNC machining is useful, especially in the production of router machines. More accurate and economical outcomes than ever before are now possible thanks to CNC machining for aircraft components. Automated manufacturing has gained popularity due to the wide variety of parts, components, and structures that all require different levels of machining, moulding, and additive manufacturing. For instance, the Boeing 747 has 6 million different parts.

When it comes to what is CNC machines’ capabilities? The benefits are revolutionary. The aerospace industry values CNC machining services because of the following causes:

- Increased Precision: CNC machines are able to produce parts with a high level of accuracy and repeatability, which is essential in the aerospace industry where even small deviations can have significant consequences.

- Improved Efficiency: CNC machines are able to operate at a faster speed and with a higher level of efficiency than traditional manufacturing methods, resulting in a shorter lead time and lower production costs.

- Enhanced Safety: CNC machines are equipped with safety features that can help prevent accidents and injuries in the workplace. This is especially important in the aerospace industry where the risk of accidents is higher due to the complex and sensitive nature of the parts being produced.

- Greater Flexibility: CNC machines are able to produce a wide range of parts and can be easily programmed to produce different parts or make changes to existing parts. This flexibility allows for a greater range of products to be produced and allows for quick changes to be made to meet changing customer needs.

- Reduced Scrap: CNC machines are able to produce parts with a high level of accuracy and repeatability, resulting in a lower rate of scrap and waste. This not only saves on production costs, but also helps to reduce the environmental impact of manufacturing.

- Increased Competitiveness: The use of CNC machines can help aerospace companies stay competitive by allowing them to produce high-quality parts more efficiently and at a lower cost. This can help companies win contracts and expand their market share.

Conclusion

In conclusion, CNC machines are important to the aerospace industry because they enable the production of precise and complex parts with a high level of repeatability. These parts are critical to the safety and performance of aircraft and other aerospace vehicles, and the use of CNC machining allows for their efficient and cost-effective production. Overall, the use of CNC machines in the aerospace industry helps to ensure the reliability and performance of aerospace vehicles, making them an important technology in the industry.