Metrologists utilise several different types of gauges in their work. Gauges are metrology devices that measure an object’s linear or angular dimensions. They come in a range of shapes and sizes, each with its own set of benefits and drawbacks. Plug gauges, ring gauges, wire gauges, feeler gauges, radius gauges, and snap gauges are the six most frequent types of gauges discussed in this blog article. These and other gauges are used by metrologists to obtain exact measurements of physical quantities in the lab or on the job.

What is a Gauge?

Assume you’re a quality control inspector who goes to the shop floor on a regular basis to conduct inspections. During one of these visits, you considered inspecting items made by one of the operators.

What method would you use to validate it? To check, you’ll need certain instruments. Right!. Gauge is the tool you’ll need to ensure that parts meet the relevant criteria. The following is the official definition of Gauge.

A gauge is an inspection instrument that measures a product’s dimensions against the maximum and minimum permitted limits. It is commonly used in mass manufacturing to separate acceptable and non-acceptable products without knowing the exact dimension value.

The gauges are non-scaled firm design inspection equipment used to examine the measurements of produced items. Gauges do not provide an accurate number for the dimension of the work that is being inspected. They’re utilised to see if the examined items are manufactured within the prescribed tolerances.

Gauges assist us in making critical decisions needed to create products that meet client specifications. If a supervisor needs to approve manufacturing, he can do so by inspecting pieces for compliance with client specifications using various gauges. If a client has to double-check parts provided by a certain supplier, he can do so with a variety of gauges.

We employ a variety of gauges in part manufacture, depending on the application. This article has covered a wide range of gauges. Continue reading to learn everything you need to know about gauges.

If you think I’ve missed any of the gauges, please let me know. Please leave a message in the space below. I’ll make every effort to include it.

Why do We Need Gauges?

Assume you have a car with no indications on the dashboard, such as a fuel gauge, engine temperature, or anything else.

How probable is it that you’ll run out of gas in the middle of your journey? I’d say that happens rather frequently. I realise it’s not a pleasant situation. The fuel level indication, by the way, is an indicator type gauge.

As a result, if production plants operate without gauges, a similar scenario will emerge. Parts produced will be riddled with flaws, and manufacturing will be halted on a frequent basis. There will be chaos on the production floor.

The following are some of the reasons why we utilise gauges:

- Assists in the constant production of high-quality components.

- Reduces production waste by detecting incorrect parts before they are manufactured.

- Assists the factory in taking a proactive rather than a reactive approach to manufacturing.

- All of the quality characteristics indicated in the control plan may be monitored using gauges.

- All of the customer-specified parameters are included in the control plan.

What are the Types of Gauges?

The various gauges used in different sectors are listed below.

- Plug Gauge

- Ring Gauge

- Snap Gauges

- Feeler Gauge

- Screw Pitch Gauges

- Radius or Fillet Gauge

- Calliper Gauge

- Dial Gauge

- Height gauge

Lets discuss each type of gauges in detail:

Also Read:

- 24 Most Common Types of Pliers and Their Uses (With Pictures)

- Different Types of Milling Cutters Used in Machining Process

- Different Types of Screws in Fastening Process

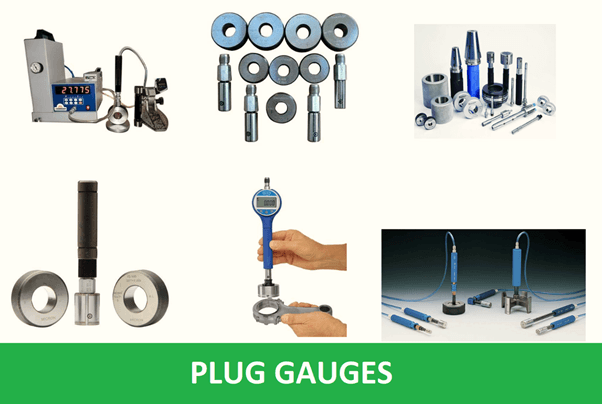

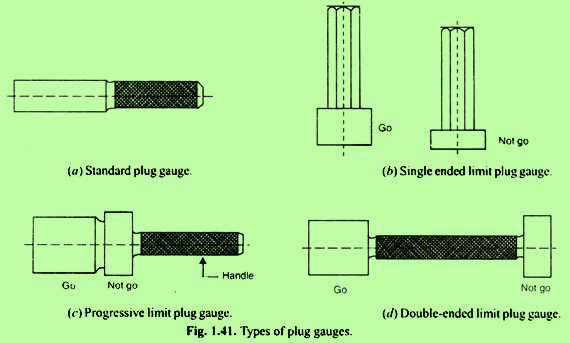

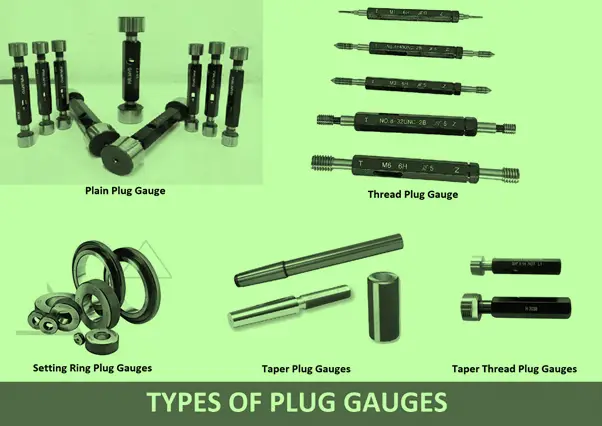

1. Plug Gauge

A plug gauge is a dumble-like cylindrical gauge. On one side, there is a go gauge and on the other, there is a no-go gauge. Gauges are inspection instruments that do not include a scale and are used to verify the measurements of produced items.

It’s used to find out how big a hole is on the inside. It’s a gauge with an attribute type. It’s called an attribute gauge since it’s the sole way to tell if a portion is good or bad. It doesn’t have any sort of variable value. A “GO” gauge indicates the product’s maximum material condition, while a “NO GO” gauge indicates the product’s minimum material state.

If the go-gauge enters the hole smoothly and the No-Go gauge does not, the part is in good working order and meets the specifications. If the Go-Section does not enter the hole or if the No-Go section enters the hole, the portion is either NG or NC.

They don’t show the actual value of the examined dimensions on work, but they do make sure the size of the component being inspected is within the given limitations. Plain gauges are used to inspect holes and shafts that are not threaded.

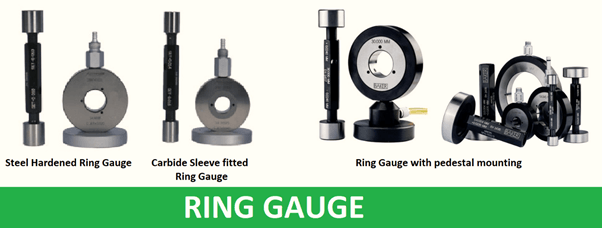

2. Ring Gauge

A ring gauge is a steel cylinder ring with an interior diameter polished to gauge tolerance that is used to measure the outside diameter of a cylindrical item. Pins, shafts, splines, fasteners, dowels, studs, and other machined cylindrical pieces may all be measured with ring gauges.

Ring gauges are used for comparing gauges as well as testing, calibrating, and establishing gauges and other standards. Individual ring gauge sets in metric and English dimensions are constructed to a range of tolerance grades for master, setting, and working purposes. Ring gauges are divided into three categories: go, no go, and master or setting ring gauges.

Go ring gauges are high-precision equipment for production comparison gauging with a predetermined limit. Go gauges are made up of a fixed limit gauge with a gauging limit dependent on the examined part’s plus or minus tolerances. The dimensions of a go ring gauge are determined by the round bar or item being gauged’s maximum OD tolerance. The dimensions of a go plug gauge are determined by the hole or part’s minimum ID tolerance. The plus gauge manufacturers’ tolerance from the minimum part tolerance should be indicated for the go plug (ID) gauge. A negative gauge makers’ tolerance from the maximum component tolerance should be indicated for the go ring (OD) gauge.

A precise instrument for production comparison gauging based on a predetermined limit is the no-go or not-go gauge. No-go gauges are made up of a fixed limit gauge with a gauging limit depending on the examined part’s minimum and maximum tolerances. The dimensions of a no-go ring gauge are determined by the round bar or item being gauged’s minimal OD tolerance. The ring of no-go (OD) A ring gauge is a steel cylinder ring with an inside diameter polished to gauge tolerance that is used to measure the exterior diameter of a cylindrical object. Ring gauges can be used to measure pins, shafts, splines, fasteners, dowels, studs, and other machined cylindrical parts.

Comparing gauges, as well as testing, calibrating, and setting gauges and other standards, are all done with ring gauges. Individual ring gauge sets are built to a range of tolerance grades for master, setting, and working applications in metric and English inch dimensions.

There are three types of ring gauges: go, no go, and master or setting ring gauges. The gauge should be provided with a makers’ tolerance that is greater than the minimum component tolerance.

Gauge blocks, master or setting discs, and setting rings are all examples of master gauges that are used to calibrate or set micrometers, optical comparators, and other gauging devices. In the shop, working gauges are used for dimensional inspection and are verified against a master gauge on a regular basis.

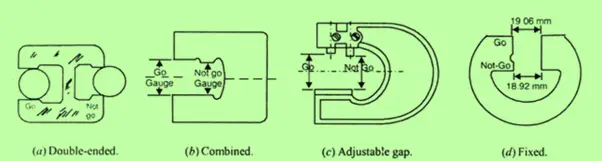

3. Snap Gauge

Exterior dimensions, such as outer diameter and thickness, are checked with a snap gauge. Gap gauges are another name for them. A snap gauge is a C or U-shaped frame with jaws that is used to inspect shafts and male members for accuracy. The snap gauge determines whether or not the shaft diameter falls within the required tolerances. The size of the ‘Go’ snap gauge correlates to the shaft’s high (highest) limit, while the ‘Not-Go’ snap gauge corresponds to the shaft’s low (lowest) limit. This implies that a single gauge can examine both the top and lower tolerance limits on the dimensional parameter being measured.

Snap gauges come in a variety of styles. Single-ended or double-ended snap gauges are available. Jaws on a snap gauge might be fixed or adjustable. Generally, Both the Go and Not-Go functions are available in a single jaw. One of the advantages of employing snap gauges is the rapidity with which they can inspect.

Snap gauges are lightweight, simple to use, and robust enough to allow for the interchangeability of various parts. Tubular frames are offered in sizes ranging from 150 to 600 mm.

Also Read:

- Different Types of Bearings

- Different Types of Screws Heads – That You Must Know

- What is Slotter Machine – Parts, Types, Working, Operations, Advantages and Disadvantages?

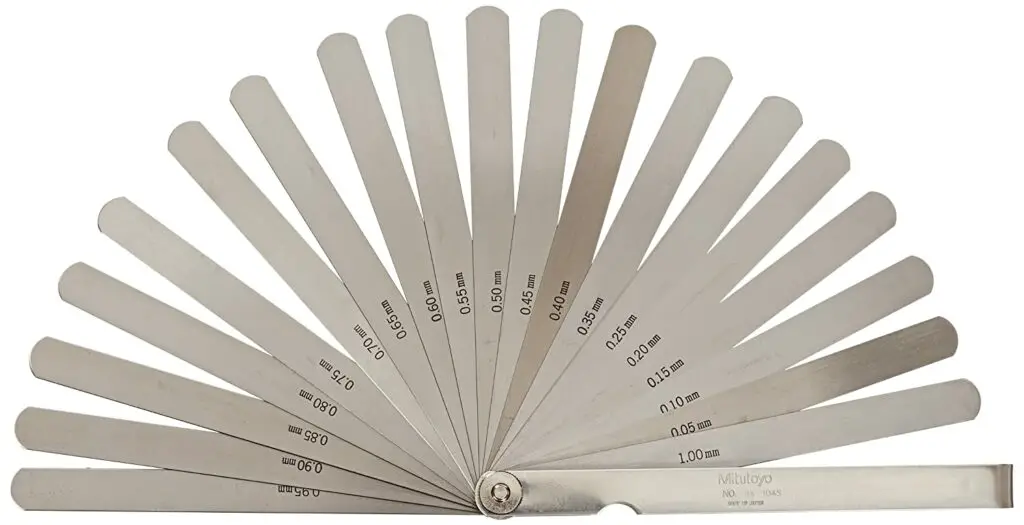

4. Feeler Gauge

When checking clearance between two mating surfaces, a feeler gauge is utilised. A thickness gauge is sometimes known as a feeler gauge. It is available in a variety of diameters, ranging from 0.04 mm to 1 mm. They are made up of a set of precisely machined steel blades that are 0.03 to 1.0 mm thick and 100 mm long. The blades are kept in a holder, as illustrated in the illustration. The thickness of each blade is indicated.

The Indian standard provides seven sets of feeler gauges: 1, 2, 3, 4, 5, 6, and 7, which differ in the number of blades and thickness range they cover. The thickness of thin blades varies by 0.01 mm in the 0.03 to 1mm set, and by 0.05 mm in the 0.1mm set.

To determine the clearance size, one or two blades are inserted and tested for fit between the contacting surface until blades of appropriate thickness are discovered.

The clearance between mating components is a critical metric, and too much space in particular areas might cause serious issues. Gas leakage might occur if the clearance between the cylinder head and the cylinder block is too large.

Feeler gauges have the extra benefit of being able to be used to measure completed pieces. The flatness of the individual mating surfaces of the cylinder block and cylinder head may be examined using a variety of ways, but only a few methods, like the feeler gauge, aid with inspection after assembly.

5. Screw Pitch Gauges

A screw pitch gauge, often known as a thread gauge, resembles a feeler gauge in appearance. Each strip or blade contains a number of teeth that are precisely tailored to the thread form.

A screw pitch gauge is a common instrument for selecting and verifying the pitch of screw threads. They are made up of a number of flat blades that are cut to a specific pitch and pivot in a holder, as seen in the diagram. The pitch, or number of threads per inch, is branded on each blade, and the holder has an identification number that designates the thread it is meant for. The sets are designed for metric threads with a 60-degree angle and contain threaded angles for English threads with a 55-degree to 60-degree angle.

A set of 20 blades for measuring metric threads has pitches ranging from 0.4 to 6 mm, whereas a set of 16 blades for measuring English threads has pitches ranging from 4 to 28 threads per inch.

The closest comparable gauge blade is selected and attached to the thread to be examined for checking its pitch. It’s possible that you’ll have to try a few different blades before you find the right one.

6. Radius and Fillet Gauges

These gauges are used to verify the curvature radii of convex and concave surfaces, as well as shoulders, covering a range of 1 to 25 mm. The gauges are constructed up of a series of thin plates with varying radii at the ends, as indicated in the diagram. There are 16 convex and 16 concave blades in each set. A radius gauge is commonly used for layout work, component inspection, and as a template for grinding cutting tools.

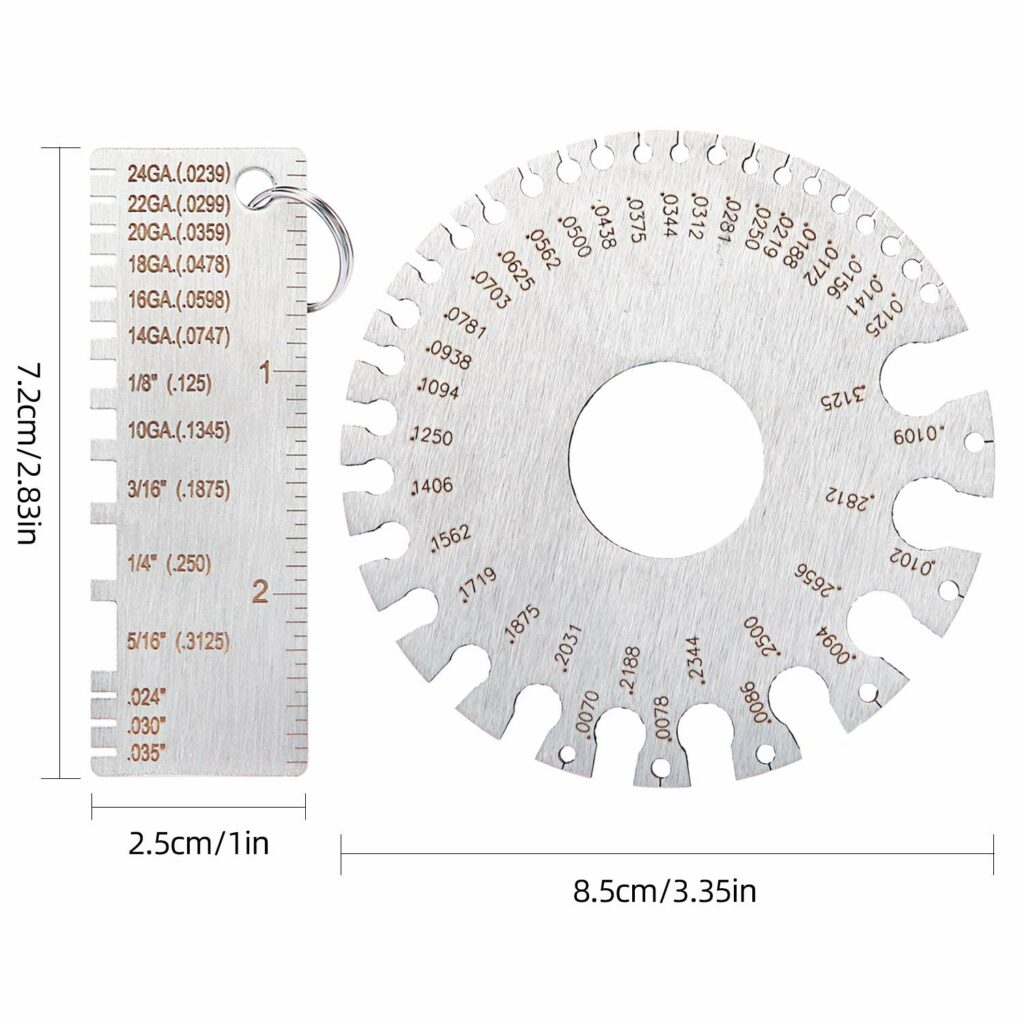

7. Plate Gauge and Wire Gauge

Plate gauges are used to evaluate sheet metal thickness, and wire gauges are used to check wire diameters. The plate gauge in the picture is used to check plate thickness from 0.24 to 5.0 mm, and the wire gauge in the figure is used to check wire thickness from 0.1 to 10 mm.

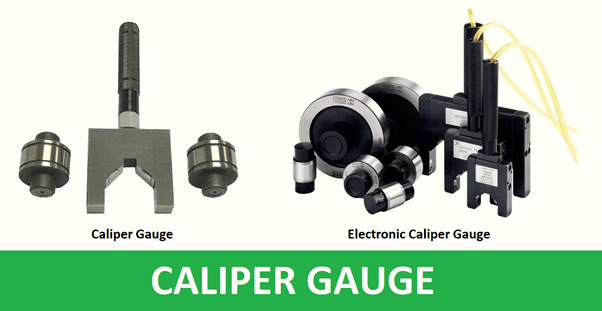

8. Calipers

Calipers are used to measure the dimensions of parts. In industrial plants, it is one of the most widely utilised tools. It usually measures both inner and exterior measurements and includes an external scale for comparison.

Calipers come in a variety of shapes and sizes.

Inside caliper

Inside callipers are used to measure an object’s inside dimensions.

Outside Caliper

Outside callipers are used to measure an object’s exterior size.

Divider caliper

Compass, divider, and calliper are tools having two legs that rotate to each other at the top and are used to measure or transmit tiny distances.

Odd Leg Caliper

It has two legs, one of which is bent for use on stepped surfaces. Odd Leg Calipers (Hermaphrodite Calipers) are mostly used to scribe lines parallel to the edge of metal (or plastic) – similar to how a carpenter may use a Marking Gauge. By initially determining the radius of a disc and then scribing a number of arcs from various places around the perimeter, odd legs may be used to determine the disc’s center. The multiple arcs will encircle a tiny region in which the center must lie so that the center may be determined.

Vernier Caliper

A vernier caliper is a tool for calculating the distance between two points on a linear scale. It may be used to measure the measurements of the outside, inside, and depth.

The least count on an analog Vernier Caliper is 0.02 mm, whereas the least count on a digital Vernier Caliper is 0.01 mm.

Micrometer Caliper

For exact measurements, micrometer, calipers are employed. As the name implies, it has the lowest count of 0.001 mm, or one micron.

Micrometers of various varieties are used to verify interior, exterior, and depth dimensions.

9. Dial Gauge

The dial gauge is a sort of indication gauge that comes in a variety of least counts. Plunger dial gauges and puppy dial gauges are the two types of dial gauges.

A dial gauge is a tool that is used to measure how much an object deviates from expected norms.

Dial gauges are used to assess surface profiles, pressure, and other parameters.

10. Height Gauge

The height gauge is used to determine the height of different items. It’s utilised with a scriber, dial indicator, and other tools.

The least count on the height gauge ranges from 0.1 mm to 0.01 mm.

Maintaining Gauge Condition Checklist

- On the calibration label, check the state of the calibration. The instrument must be calibrated, and the expiration date must be later than now.

- Benzene solution or any other cleaning solution can be used to clean gauges.

- Place gauges in the appropriate box or location.

- Gauges must be maintained a distance from the vibration source.

- Keep gauges out of the sun and away from severe heat.

Advantages of Gauges

- They are independent of mistakes.

- They are portable and self-contained in terms of electricity.

- They are simple to set up and do not require any additional equipment.

- Dimensions may be examined in a variety of ways.

- They’re more affordable than measurement devices.

- They maintain a set of standards.

- It is possible to check whether the product is within its stated limit more quickly. 8. There is less reliance on operator competence, and so the outcome is not influenced by operator judgment.

- More than one dimension of the product can be checked at a time as well as properties such as roundness, taper, etc. as can be checked at a time

Disadvantages of Gauges

- The workshop gauges may reject certain components that are within the work tolerance limits. As a result, they must be inspected again using inspection gauges before being accepted.

- When components are evaluated using inspection gauges, certain components that are outside of the work tolerance limits may be allowed.

- Because the tolerance zones for the workshop and inspection gauges are different, they must be constructed individually.

- The exact value of a product dimension is unknown.

- As time passes, the accuracy of gauges deteriorates owing to wear and tear.

Here we have learned about the different types of gauges, their uses, application, advantages, and disadvantages. If you find this information useful then don’t forget to like and share.