Introduction

If you are a mechanical engineer or pursuing mechanical engineering then you have seen so many machines in your workshop such as lathe machines, shaper machines, drilling machines, etc. Now if you closely observe a pulley then you will find a cut or depression is there at its inner diameter, It is called keyways. So when there is a requirement of cutting slots, keyways, making external and internal gear profile than we require a machine that efficiently does this and the slotter machine is one of such machine which is capable of doing that very perfectly and efficiently. In this article we will study about slotter machine (slotting machine) its main parts, working, types, advantages, disadvantages, and application in detail. So let’s start…

What is Slotter Machine Or Slotting Machine

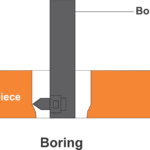

It is a reciprocating type of machine tool in which the ram that holds the tool moves in the vertical axis. It is almost similar to the shaper machine. In the shaper machine, the ram reciprocates in the horizontal direction, and in the slotter machine the ram reciprocates in the vertical direction. The cutting action in the slotter takes place during the downward stroke of the ram, and there is no cutting in the return stroke and called an idle stroke.

Slotter Machine Parts and Diagram

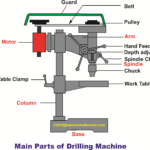

For understanding the working of any machine, we need to first understand the construction and function of its main parts. So let’s see the main parts of the slotter machine

- Base or Bed:

- Column

- Saddle

- Cross Slide

- Rotating or Circular Table

- Ram

- Tool Head

- Ram Drive

- Feed Drive

1. Base or Bed:

The base of the slotter machine should be very rigid and strong since it holds all the loads and vibration of the machine. so the base is made with cast iron because it has high rigidity as well as vibration-absorbing capacity as compared with other metal. It supports all the parts of the machine such as column, table, saddle, cross slide. etc.

2. Column

It is the vertical part of the slotter machine that contains all the drive mechanisms for the ram and feed. At the front face of the Column, It has guideways on which the ram moves reciprocating motion (to and fro motion). Same as the base it is also made from cast iron.

3. Saddle:

The saddle is mounted on the base of the slotter machine and it is used to give longitudinal feed to the table. In other words, it allows the table to move towards and away from the column.

4. Cross Slide.

It is present on the saddle and used to move the table in cross direction to the saddle movement. To understand the movement of the cross slide lets us assume that we are standing at the wheel of cross slide than it moves away from us and towards us when we rotate its wheel either in clockwise or anticlockwise direction. It can be operated either manually or automatically to give crossfeed.

5. Circular Table

It is mounted over the cross slide. It is used to hold the workpiece. It has T-slots that helps to hold the workpieces firmly during the slotting operation. The table can also be rotated according to the requirement of the operations. It can be either operated manually or power to give it longitudinal and transverse motion.

6. Ram

Ram is the most important member of the slotter machine. It reciprocates on the guideways at the front face of the column. Ram reciprocates in vertical direction i.e. upward and downward during the operations. Tool head is attached to the lower end of the ram on which a single point cutting tool is attached to perform the slotting operations. The cutting operation takes place during the forward stroke of the ram and there is no cutting during backward or return stroke.

7. Tool Head

Tool head is used to mount the cutting tool. In a slotter machine, the tool head is present at the lower end of the ram. According to the requirement, different types of a cutting tool is attached to the tool head.

8. Ram Drive

The ram reciprocates in the vertical direction and cuts the metal workpiece in forward stroke only. Now a question comes in our mind that what is responsible for this vertical motion of the ram. So there is some driving mechanism in the column of the slotter that drives the ram. The ram reciprocates on the guideways at the front face of the column.

9. Feed Drive

It is an arrangement made in the slotter to given longitudinal movement to the saddle, cross-movement to the cross slide, circular and up and down movement to the table.

Also Read:

- Planer Machine: Definition, Parts, Working, and Operation

- Types of Drilling Operations Performed in Drilling Machine

- Types of Milling Cutters Used in Machining Process

Mechanism Used

In the slotter machine, a quick return mechanism is used to drive the ram for cutting the metals from the workpiece. It is called a quick return mechanism because here the time taken by the ram in return stroke is less as compared with the forward stroke i.e. return stroke move quicker than the forward stroke. The cutting takes place in forward stroke and no cutting in the return stroke.

There are various types of Quick Return Mechanism and most commonly used are:

- Crank and slotted Lever Quick Return Mechanism

- Whitworth Quick Return Mechanism

- Slotted Disc Quick Return Mechanism

- Hydraulic Quick Return Mechanism

Working of Slotter Machine

The working of the slotter machine is the same as that of the shaper machine but the difference is that shaper cuts the metal horizontally and slotter cuts the metal vertically. Let’s try to understand the working of the slotter machine in detail:

- First, the workpiece that is to be slotted mounted on the table. The table has t slots that helps the w/p to hold firmly on it.

- After Clamping the workpiece on the table. An appropriate cutting tool is inserted into the tool head for cutting the metal. Here the tool is made of HSS (High-speed steel)

- And then the machine is ON that allows the ram to move upward and downward in a vertical direction.

- As the ram moves downward called a downward stroke, It cuts the metal from the workpiece and then returns quickly ( called as return stroke) without cutting the metal. So we can say that the slotter machine cuts the metal in downstroke and remains idle i.e. does not cut any metal in return stroke.

- Feed in slotter can be worked automatically or manually. There is a mechanism inside it that allows the movement of the table, cross slide according to the ram movement automatically. The movements of each part are interlinked with each other and there is no chance of any error in the feed

Also Read:

- Types of Lathe Machine – Mother of all Machines

- What is Milling Machine – Operation, Parts and Types.

- Laser Beam Machining – Main Parts, Principle, Working with Application

For better understanding about the working of slotter machine Watch the Video till the end:

Types of Slotter Machine

The main types of slotter machines are

1. Punch Slotter

It is very heavy in weight and used to remove large amounts of metal from the workpiece. It is mainly used to remove metals from large casting or forgings. The length of the puncher slotter is quite large and it ranges from 1800 mm to 2000 mm.

The ram of the punch slotter has rack teeth that are cut on the underside of it. The ram is driven by a spiral pinion gear meshing with the rack teeth of the ram. A variable speed reversible electric motor is used to drive the pinion.

2. Precision Toolroom Slotter

A precision slotter is a lightweight machine that is used for light cuts and accurate surface finish. It works on high speed and uses Whitworth quick return mechanism for its working.

3. Production slotter

As the name indicates, this slotter is used for production work. It is used for machining tapered jobs since ram in these types of slotter can swivel to 10-30 degrees

4. Special Purpose Slotter Machine

Special purpose slotter machine is used for large volume production of any part with high accuracy and at low cost. Keyseater is an example of special purpose slotter machine that is used to cut keys on the gear hub and wheel.

Operations Performed on Slotter

Before understanding the various operations performed on the slotter lets us first try to understand what is grooves, slots, holes, and keyways.

- Grooves: It is a narrow cut or depression on the circular and flat surface. The operation performed to create grooves is called grooving.

- Slots: An Enlongated hole on a flat surface is called slots and the operation is done for cutting slots is called slotting operation.

- Keyways: It is defined as a slot cut in a part (shaft or hollow shaft) to make a correct orientation with another part that is to be fitted with a key.

- Cutting grooves: It is used to produce grooves in the machine parts.

- Making keyways: when Two parts are needed to be mesh together with correct orientation then a key is used for it. So a key is required in both the parts and it is produced with the help of a slotter machine.

- Cutting slots: It is used to produce slots of various sizes in the required machine parts.

- For cutting external and internal gear and profile.

Application of Slotter Machine

- Slotter machine is used to produce slots, keyways, and gear teeth.

- It is used for machining internal and external flat surfaces and circular surfaces.

- If there is a need for shaping external and internal types of profiles then slotter is the best choice.

- It is used for machining irregular surfaces, blind holes, dies and punches, external and internal gear teeth.

Advantages of Sotter Machine

- It is a lightweight machine and can be easily transportable.

- It uses a single point cutting tool which is economical.

- It gives you an accurate surface finish.

- The cost of this machine is low as compared with other machines in this category.

Disadvantages of Slotter Machine

- A Very Skilled worker is required to operate the slotter.

Difference Between Slotter, Planer, and Shaper Machine

Description | Slotter | Planer | Shaper |

| Tool Motion | Vertically | Intermittent Translatory Motion | Horizontally |

| Machining Accuracy | Low | High | Low |

| Power Consumption | Low | High | Low |

| Weight | Lighter in construction | Heavier in Construction | Lighter in construction |

| Rigidity | Less Rigid | More Rigid | Less Rigid |

| Job Suitability | Small jobs | Large jobs | Small jobs |

| Floor Space Requirement | Less floor space | Large floor space | Less floor space |

| Tool and W/p motion | Tool moves and w/p stationary | Tool stationary and w/p moving | Tool moving and w/p stationary |

| Types of Tool Used for machining | Single point cutting tool | Multipoint cutting tool | Single point cutting tool |

| Number of surfaces Machined at a time | One surface | Three surfaces | One surface |

| Cost of Machine | Less than shaper | High | Less |

Summary

A slotter machine is a machine tool that works on the principle of a quick return mechanism to cut metals from a workpiece. It cuts metals only in the forward stroke only. It is used to produce keyways, slots, grooves, internal and external gear profiles and etc.

Conclusion

Here we have discussed all the possible information about the slotter machine, its main parts, types, operations, advantages, disadvantages, and application in detail. I hope you have liked this piece of information. If you find anything missing then let us know through your valuable comment and you can also mail us.