Definition Of Planer Machine:

Planer is a machine tool used for producing accurate flat surfaces and cutting slots. It is similar to the shaper machine but in case of size, the planer machine is larger. The workpiece slots move here from one point to another for operation, whereas in the shaper machine the workpiece slots were in a stationary position.

The tool we use here is a single point cutting tool which I have covered in every detail. Checkout those articles.

The Planer machine was invented by General Bentham invented planer. It is one of the Important machine tool in Manufacturing Process.

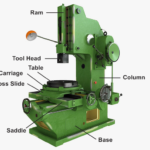

Parts of Planer Machine:

A planner machine is consist of the following Parts:

- Bed

- Column

- Overarm supports

- Table

- Cross rail

- Work hold table

- Tool head

- Vertical tool head

- Feed gearbox

- Table drive

Bed:

Bed is a rigid part of the machine on which all the parts are carried. This is very large in size and heavyweight.

Column / Housing:

The housings is called columns and It is also called uprights and are rigid box-like vertical structures placed on each side of the bed and fastened to it. Here pulley and gear are also attached.

Table:

It supports the work and reciprocates along with the ways of the bed. The table is made up of high quality cast iron. Here the table upper surface parts are very fine and accurate because here we fix the workpiece for the planner operation.

Cross rail:

In cross rail, tool holders are attached where we can fix the tool for operation. It connects between two housing and also provides supports to the housing.

Tool Head:

Here the tools (Single Point cutting tool) are fixed.

Also Read:

- Types of Milling Cutters Used in Machining Process

- What is Ultrasonic Machining (USM) and How it Works?

- What is Drilling Machine and How It Works?

Working Principle

- The working principle of the planer machine is the same as the shaper machine which is a Quick return motion mechanism.

- While the workpiece moving forward the forward strokes complete and while it moving back the return stroke complete. In a forward stroke, the material is cut and in backward no material is cut.

How it Works:

- Here tool head is in a stationary position and the workpiece is moveable.

- In the tool head section, we fix the single point cutting tool and at the work table, we fix here workpiece.

- We supply the power, the worktable moves forward and with the help of the cutting tool, it cut the material and again it returns back that is called return stroke.

- Until or unless you change it, the rotation will go forward and backward stroke.

For a better explanation about how the planner machine works. Watch the Video:

Planer Machine Operation:

- The operation performs here to remove the material as we do in the shaper machine, but the main thing is in the shaper machine there is only having one cut section and whereas in the Planner machine having multiple cutting sections which provide a greater surface finish and fast work to obtain a flat surface result.

There are two operations we perform here

- Vertical flat and

- Horizontal Flat surface planning operation.

Vertical Flat Operation:

- When we perform vertical flat operation on the planner machine, a workpiece is planned by adjusting the saddle horizontally along the cross rail until the tool is in a position to give the required depth of cut. The vertical slide is adjusted perpendicular to the planer table and the apron is swiveled in a direction so that the tool will swing clear out of the machined surface during the return stroke.

Horizontal flat Operation:

- When we perform horizontal flat operation on the planner, the workpiece is given reciprocating movement along with the table and the tool is fed crosswise to perform operation.

Also Read:

- What is Slotter Machine?

- 37 Types of Hammers that You Don’t Know?

- 6 Types of Screwdrivers – Everyone Must Know

Types of Planer Machine:

These are the general types of Planer machine:

- Standard or Double housing type planer

- open side

- Pit planer

- Divided table planer and

- Edge planer Machine

Standard or Double Housing Type Planer:

- This planer is the most widely used type of planer in workshops.

- It is a kind of old type of machine.

Open Side:

- This machine used for machining a wide workpiece.

Pit Planer :

- It is rigid in construction. In this, the table is stationary and the column carrying the Cross rail reciprocates on massive horizontal rails mounted on both sides of the table.

- Pit Planer machine are suitable for machining a very large work which cannot be supported on a standard planer.

Divided Table Planer:

- The divided table planer has two tables on the bed which may be reciprocated separately or together and also join together when needed.

- It is used for continuous mass production.

- The type of design saves much of idle time while setting the work. The setting up of a large number of identical workpieces on the planning machine table takes quite a long time.

- It may require as much time for setting up as may necessary for machining.

Advantages

Here are the advantages of Planer Machine:

- Provide a better surface finish.

- Low maintenance.

- Good Accuracy

- At a time 2 or 3 tools (Single Point cutting tool) are performed which is very good to get work fast.

- Here also the main advantage is that we can use one tool at a time.

Disadvantages

These are some disadvantages of Planner Machine:

- The price is high.

- Only one tool Single point cutting tool is used.

- Skilled worker(Must have knowledge of machines) required for operating machine

- Power consumption is more.

Application of Planner Machine:

Following are the advantages of Planner Machine:

- Using this machine for generating a good flat surface.

- A planer machine can remove a good amount of material from the workpiece at a time with good accuracy because here the multiple tools are fitted.

- More number of cutting slots.

- It is also used for Cutting at an angle.

Hi! Do you use Twitter? I’d like to follow you if that would be ok. I’m undoubtedly enjoying your blog and look forward to new posts.|