Introduction

In the modern era, everyone needs more work in constant time with the best quality. Each organization wants to increase its productivity in significant time and product costs. So as days are going passing, industries being converted into digitalization. Old and heavy machines which are not able to maintain accuracy and time continuity. One machine can save the effort of many men and maintain the economy rate. These require only a few operators who are expert to handle these machines.

CADD stands for Computer-aided drafting and designing. In general, it is called CAD. Contain a complete process of manufacturing of a product. These are categorised into three parts …

1. CAD

The basic and initial requirement of manufacturing is CAD. Formally it is used for drafting and sketching the object. With the help of these software 2D and 3D designing can be prepared. These are used by various streams of engineers such as mechanical, electrical, civil and electronics, etc. It allows you to imply your ideas on the system by means of 2D or 3D drawing.

AutoCAD, SolidWorks, and Creo are some software that counts in CAD category.

2. CAE

It stands for Computer Aided Engineering. Through this, engineering operation of testing applied like as the product is how reliable and its strength, mechanical properties are controlled and checked by this.

Ansys, Hyper mesh and NS NXT, etc are the examples of CAE Software.

3. CAM

This is stands for Computer Aided Manufacturing. When the design is created and the testings were completed then the object is processed for manufacturing. These conclude automated machines, used for producing the final product.

NX cam, SolidCAM are the example of cam software.

History

The earlier designing process on computer being started in the 50’s decade. The initial idea of designing on system come on the ground by Dr. Paul J Hanratty in 1950. It was able to draw only lines and it has made a sense to design the mechanical components on computers.

After that many researchers and organizations started to working on it. In 1957 MIT(Massachusetts institute of technology) researchers comes with a new idea of making it programmable by using coding and these programs will enable designing tool.

Also Read:

- Top 5 Best Vacuum Cleaner for Car to Buy

- What is Plastic Injection Moulding and How it Works?

- 6 Types of Screwdrivers – Everyone Must Know

Modern CAD

After observing its popularity and analyzing its future benefits many research has been started and organizations starts to investing in improving the designing software. During the period of 1960 to 1980 many designing tools have been added which were very effective and some of them still using nowadays.

The most amazing fact is that they were working only on 16 bit PC’s. As days passed PC’s improved and come with specific features in refresh form.

AutoCAD ERA

A software company Autodesk in 1982 represents CAD system software. It has enough features according to that day’s requirement. In 1986 PC world magazine has called it the world’s best designing software which is still going on.

This software works for 10 years with the same tools and features and in 1993 it has aided 3D modeling feature which exploded amazing effects on designers. It allows taking better and different views from a different angle.

It is very easy to redesign the project by 3D modeling and can make necessary changes in design. CAD organization is still working on it and comes with some new features and tools every year. There are some organisation that provided CAD services where people can develop their design models and projects very easily.

What is CAD?

In exact meaning, CAD is a type of software for designing as well as drafting software used by professionals, engineers, architects and product designers.

It allows the computer systems to draw complex designs which may take many hours by hand drafting but in only few minutes with the use of keyboards and mouse. It grants and conveys the important role in…

- Creation

- Development

- Modification

- Analysis and

Optimization of design and manufacturing activity.

Through using these softwares, it is very easy to make 2D and 3D drawings. In AutoCAD sometimes it takes time in 3D drafting because the 3D modeling tool is not proficient and much friendly with drafters. We need to go for different software for different designs. In modern market different types of software available and can be chosen according to our requirement. Industries do not take all the tools, they use only specific and concentrated tools. Software purchased on account of the consideration of industry economy. These are very expensive and wisely investment is grant need.

WHY CAD?

This technology made to design and drafting the object because by using this software the designs can be drawn very easily on the system with the use of graphics in fine quality.

Computer Aided designing has reduced the time and cost of production under consideration to enhance productivity. The creative ideas can be implemented and are able to make complex models. Finished models can be redesign together with before and after the process of designing. It has well acknowledgment about product management so there is no need to worry about its inventory. Another advantage is that it can be transferred from one office to another within a second.

During production, you can redesign the model and be developed with respect to save the time and cost of production. These are its advantages which elongate the production rate and industry investment.

At initial design is prepared by designing software after that modification analysis starts in which required changes conveys. For analysis extra software are also available by using that testing operation applies which clarifies various mechanical properties and the strength, performance of the product. There are various tools for optimization and to change the properties of the product according to customer requirements. This is a very important stage of designing if it will not be done properly in a well manner the final can fail and will not overcome organization requirement product quality. So the product quality is solely dependent upon the optimization process which can make the product more powerful or can change the internal properties.

When optimization or analysis process accomplished then the role of computer aided manufacturing software starts. These can be Computer Numeric Control (CNC) machines or together with Dynamic Numeric Control machines. They are program based digital machines run on behalf of a given program by the operator.

Also Read:

- Difference Between NC and CNC Machine

- What is Lathe Machine? Main parts, Operations and Working

- What is Slotter Machine?

Potential Uses

There are huge and most broad uses in CIM (computer integrated manufacturing). This includes the process of computer aided engineering and finite element analysis (FEA).

FEA covers the analyzation of design with very fine and accurate elemental testing process. It can observe a minor defect in design and represent that with pinpoints by means of finite element analysis.

CAM type software instructs the CNC and DNC machines. These machines are operated by expert operators, able to read the design.

CAD systems are used for drawing the photo realistic rendering.

These act as product data management –

In managerial operation, it plays an effective role to make economical production. Manage the input and output rate of the industry. Through this quality it also keeps an eye on the inventory.

It also works as a document manager. Because sometimes it becomes critical to manage the hard copies so it keeps that information in the form of soft data. It prevents from hacking ideas.

Types

In early days it was only able to draw 2D drawing but after days passed, the technical and smart devices come in to know. These are more skillful, it’s the time of 3D drawing which is an extensive and improved form of 2D designing. 2D drawings are unable to show each section and different views of an object so it was a necessity to take differ views which becomes true with the use of the 3D tool. It allows seeing isometric views of the object.

There are not any basic types of these software but further, we will try classify these on account of its operation, use and property…

1. 2D drawing

Under this, the software has been put which works only in two axes. Unable to show the isometric views.

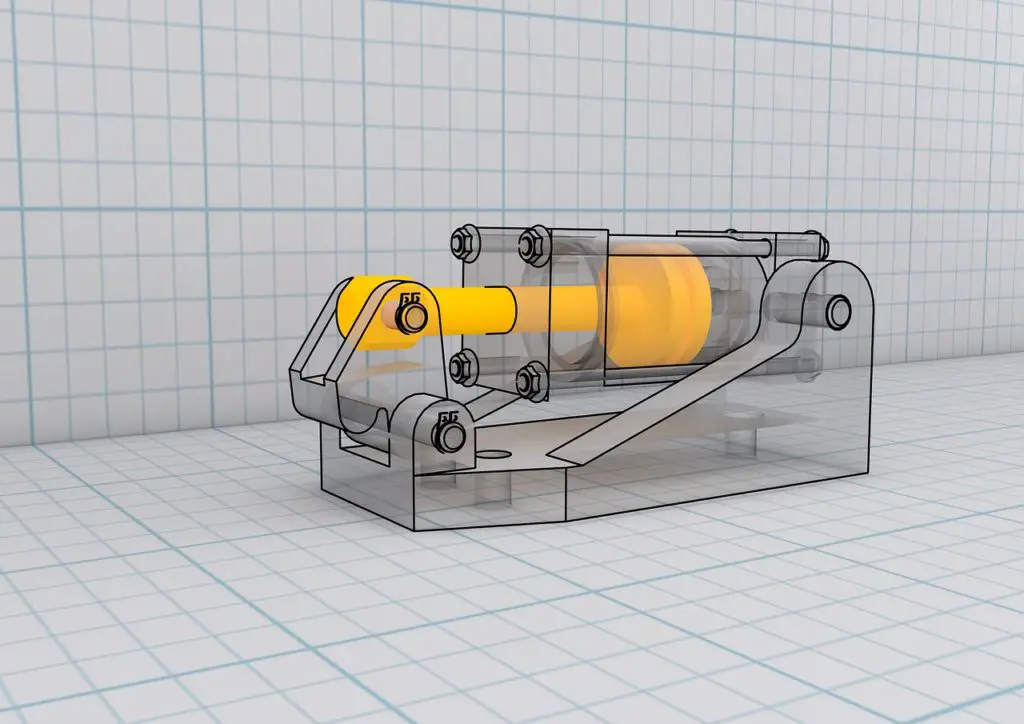

2. 3D dumb solid

In this, the objects become likely to real world object.

3. Parametric solid

These designs are advanced 3D models. In this, the objects can be modifying as our requirement. Every software is not fluent for every type of operation like using AutoCAD and draw 3D models becomes very difficult. As well as very hard to draw complex designs and making the modification.

But another designing software like SolidWorks and Creo are more friendly for 3D designing. By using their tools, it is very easy for instant modification.

4. 3D CAM Modeller

In the modification point of view, it has the best tool and through this, it does not require the past design tree to edit the design. Able to edit choosing the portion of design which is required or where a defect is created. So it doesn’t need to call the past command/action which has been used.

5. Direct 3D CAM

This is also known as an explicit modeler, allows to edit the design with the use of history tree. If due to any cause history tree lost, then after than it is also able to make changes.

History tree –it grows at the top of left most side of the graphic area. As we use the commands, tools become shown and stored as a form of history tree. By using these tools or commands we can edit a particular area, where these commands have been used. This is the main advantage of this type to make changes in a particular concentrated area.

Interaction with Computer Graphics

Interactive computer graphic (ICG), is a most important and effective part of CAD system with the help of that Computer Aided Designing interfaces with the human.

As we know that the computer knows the only language that is binary codes. It takes its commands from input devices like keyboard, mouse and converts it in the form pictures and readable form. Creating drawing and making its visible on our system screen is possible only with the help of graphics, the whole credit for visual is goes to interactive computer graphics. Nowadays in the market, there are different types of software being available which have their own requirements, on behalf of their features and capabilities. Every designing software needs graphics cards which can be of different storage. For modern software, the minimum requirement of a graphic card is 2 GB. It will increase according to types of work and reliability. Enough graphic allows drawing the design very quickly and freely. If you don’t have enough capacity, then the system may hang during the work and the images take load after some time. System response becomes very poor.

Advantages

There are such fabulous assets of computer aided designing which is continuously increasing by adding new designing tools …

- It has increased the efficiency and quality of the product.

- Reduced the man’s efforts and minimized the endeavor of many workers and can be controlled by the operator. In such a way the cost of production decreases.

- Machines always work faster than manpower so it will increase the rate of production.

- It is easy in refreshing.

- Designs can be transferred from one place to another very safely, quickly within seconds.

- Because of its nature of digitalization subcontractors have been reduced. There is no need for any third party to contact each other.

- Quality of product is a very high cause of its working nature on the microscopic level, so clarify all the minor defects.

- Analysation power becomes more improved and can be viewed by different angles.

- Provides an isometric workplace that gives appropriate visual.

- It is easy to read the design and cab be make marks or specifications for better understanding.

Application

The CAD system can be used at the office places where instant and frequent changes are required. It has the quality to make changes in design at a particular point without interfering with the main portion of the model. Sometimes we create models that look very similar to the already present model so we can make that model in a different dimension and differentiate that to add some new extra and necessary features which we want. It will save time as well as effort also.

The main point to keep in knowledge that it is a computer-based system and its processing is very frequent so if our system processing is slow then there will be many difficulties to work on it. So minimum requirements must be fulfilled for proper working. The skilled operators allow to control the system otherwise it is very difficult to handle. A single mistake can ruin the whole design. It has a broad application area some of them are as follows…

1. In Engineering Projects

From sketching to manufacturing it has all the ability to complete the project. With the help of this software, one can choose the right material for the right application. Proper analysis can be conveyed. If it is required to make changes can be employed.

2. Modeling

In this, the area of application the blueprints for aerospace, automotive, ship projects prepared and designing of the futuristic model can be made. The blueprints used for production are generally are 3D design through which fair production continues. Architectures used this software for making 3D and 2D designs of buildings, gardens, and bungalows.

These days most of the fashion designers also prefer this to work on it and create a new style design according to the latest expression to make true as soon as possible.

3. Computer Animation

In the modern media industry, everyone in a race and wants to make some new and unique things which is possible in CAD design. you can create your dream drawing on system and can be make it physical without manufacturing by means of virtual manufacturing and various application can be employed.

It has a different way of entertainment and brings their imaginary character’s in the form of animation. This is possible only the use of these types of software. So it has a significant role in making more entertaining and graphical vision improvement. The special effects which are shown in movies and commercial serials are possible by the software.

It creates different parts and on time evolution it makes wonderful and charming effects with the use of the graphic system.

4. In Product Data Management

CAD is used commercially for various companies as well as by small firms and keeps the function of the organization on right track. Companies can be integrated and can be used it for privacy purposes. No one can access the private data and you will not suffer from any loss.

Disadvantages

For better understanding we must have complete knowledge about its back draws and working range to efficient handling. Some of the major limitations are as follows…

- It does not have comprehensive power for real-world analysis. CAD is not able to know about its serving.

- It is not able to understand that the project is running will be beneficial or injurious, works on the aim to make the project by any means.

- Cad is used to transferring the data in well-defined manner from one designer to another, but these data cannot be decoded by ordinary.

- Well experienced employee is able to handle this software. A single mistake may able to ruin the whole design that makes huge economical loss.

- It takes a long period to be a specialist in the designing system.

- There is a chance of hacking, its necessary to keep an eye on its safety to store the data.

- Every machinery operation followed by electric devices so during design if electricity lags then the computer becomes down and complete data (working), which have not been saved will be lost.

- Cad technology is not suited for well esthetical.

Conclusion

Computer Aided Design has changed the era of designing. It is very helpful to draw imaginary images of a real objects. There is no limit to its application ground, you can draw as much as complex imaginary drawings together with it. Still from the last seven years does not any revolutionary is happened but designing software vendors always working on it to improve it and adding new features.

In the future, the Cad will geared up to enhance the concept of designing. It may be come with new features like a virtual designing platform which is going to change the history of drawing as well as manufacturing also.

Very precious article…👌 Hope! Further I’ll be able to read these kind of articles.