You might have seen the bearings in your bicycle, but have you ever thought of types of bearings and their applications? Most of the time, “No”. Don’t worry because, in this article, we will learn all the bearing types. So, without taking much more time let us get started.

First of all, let us take a glance at the function and meaning of bearing. What is meant by bearing? The bearing is a machine element that does the work of reducing friction between two moving parts to get the required motion. The word bearing has been originated from the verb “to bear”. Besides reducing friction between two rotating parts, bearings also play the role of supporting thrust as well as radial load.

Types of Bearings

Now, let us move forward and see the below six main types of bearing:

- Plain bearing:

- Rolling element bearing

- Magnetic bearing

- Fluid bearing

- Jewel bearing

- Flexure bearing

1. Plain Bearing:

The plain bearing is the easiest type of bearing, and it is often called a sliding bearing or slide bearing. The key feature of this bearing is that it consists of only a bearing surface and no rolling elements. You can consider a shaft rotating in a hole as a plain bearing. Pillow block, stuffing box, and ring oiler are the additional elements which are required during the plain bearing.

The plain bearing has the following other sub-types:

- Bushing

- Integral

- Two Piece

Materials used for manufacturing plain bearings:

While the production of the plain bearing, the following things are to be considered about its materials:

- The bearing material must be durable as well as resistant to corrosion.

- The bearing material must be capable of resisting at higher temperatures.

2. Rolling Element Bearing:

It is the type of bearing in which load is carried out by positioning rolling elements inside the races. Races are nothing but the two bearing rings. Generally, five rolling elements like a cylindrical roller, needle rollers, spherical rollers, tapered rollers, and balls are used as rolling elements in rolling element bearings.

Rolling element bearing has two types:

- Ball Bearings: Single, double, angular contact, Thrust, self-aligning ball bearings.

- Roller Bearings: Cylindrical Gear, Spherical, Needle, carb toroidal roller bearings.

Also Read:

- What are Fasteners and its Types?

- 37 Types of Hammers that You Don’t Know?

- Types of Screwdrivers – Everyone Must Know

1. Ball Bearings:

In ball bearing, the gap between the races is kept with the help of the ball. The width of the ball bearing is always less than the diameter of the ball used.

Types of Ball Bearings

Ball bearing again has the following types by the load as well as groove cut:

(i) Single row Ball Bearings:

As per the name, in this bearing balls are arranged in an identical manner in one row.

(ii) Double row Ball Bearings:

They have two rows of balls arranged in a specific manner, and they have two grooves cut.

(iii) Angular Contact Ball Bearings:

Such bearings are designed to bear angular as well as axial loads.

(iv) Thrust Ball Bearings:

Thrust ball bearings are used if you have to handle vertical thrust load. Sometimes, horizontal thrust load can also be operated with this bearing.

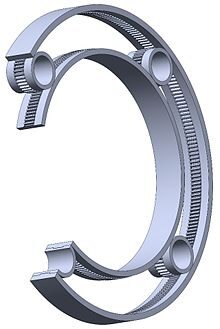

(v) Self-aligning Ball Bearings:

The below image shows this bearing. They are capable of withstanding journal loads.

B) Roller Bearing:

The roller bearings have a higher load-bearing capacity than the ball bearings. These bearings have high chances of failures in case of the absence of lubricant. Roller bearings are divided into various types by the type of roller used in them:

Types of Roller Bearings

- Cylindrical roller Bearing

- Gear bearing

- Spherical roller bearing

- Needle roller bearing

- carb toroidal roller bearing

1. Cylindrical Roller Bearing:

In this bearing type, a cylinder is used, and it has a higher diameter than its length.

2. Gear Bearing:

This bearing has an arrangement like elliptical gears, and in this bearing, smaller satellite gears are present which perform their revolution around the center of the bearing. These bearings increase efficiency as well as reduce sliding friction. It is quite challenging to manufacture the gear bearings.

3. Spherical Roller Bearing:

Spherical roller bearing has an inner ring, outer ring, cages, spherical rollers, etc. Companies like SKF, Timken, NTN Corporation manufacture this bearing, and it is used in gearboxes, pumps, wind turbines, drilling machines, and mining.

4. Needle Roller Bearing:

A needle roller bearing is made up of long, thin cylindrical rollers and it has the shape like needles. Due to the large surface area in contact with the races, they can withstand a larger load. In pumps and compressors, we find the application of the needle roller bearing.

5. CARB Toroidal Roller Bearing:

MangusKellstrom invented the CARB bearing in 1995. The key feature of this CARB toroidal roller bearing is that its radius of curvature is much larger than its possible spherical radius.

Also Read

- Different Types of Screws Heads – That You Must Know

- Types of Springs

- Different Types of Screws in Fastening Process

3. Jewel Bearing:

The main characteristic of the jewel bearing is that metal spindle is turned into a jewel-lined pivot hole. The benefits of the jewel bearings have small weight as well as size, low friction and their ability to work without any lubrication. If the given load is not axial then, it is not advisable to use the jewel bearing. These bearings are made up of sapphire or synthetic ruby. Their size may be extended up to 10 mm and they handle 500 gm of weight.

Applications of the jewel bearings:

- Jewel bearings are used in mechanical watches.

- They also find their applications in measuring instruments like gyroscopes, galvanometers, turbine flow meters, dial indicators, etc.

4. Fluid Bearing:

A fluid bearing is a special type of bearing in which there is no sliding friction, wear or any vibrations.

Fluid bearings have two types hydrostatic and hydrodynamic.

(i) Hydrodynamic Fluid Bearings:

This bearing depends on the part of the shaft resting on the fluid to pressurize fluid between its surfaces. This type of bearings is generally used in the electric motors, hydroelectric generators, cooling pumps, etc.

(ii) Hydrostatic Fluid Bearings:

The important feature of hydrostatic fluid bearings is that they can handle heavy loads at low speeds. They are more durable bearings, and therefore, they have a longer life. Another advantage is that they give very low friction.

5. Magnetic Bearing:

In the magnetic bearing, the phenomenon of magnetic levitation is used to support the load. Compressors, turbines, pumps, motors, as well as generators, use the magnetic bearings. Nowadays, they are highly used in artificial hearts. Companies like Synchrony Magnetic bearings, Waukesha magnetic bearings, S2M are the most popular manufacturers of magnetic bearings. The future scope of magnetic bearings is very bright because a lot of research, as well as experiments, are currently going on these bearings. The main scope of such bearings is in the field of magnetic levitation trains. Magnetic bearings have two types- active magnetic bearing and passive magnetic bearing.

The following are the advantages of the magnetic bearing:

- They give very small friction

- Magnetic bearings are used in a vacuum, and they can operate without any lubrication.

6. Flexure Bearing:

In flexure bearing, a flexible element is manufactured in such a way that it is suitable for specific degrees of freedom. Flexure bearings are beneficial as they are simple, cheap, and exhibit low friction. They have quite limited applications.

Conclusion

So, in this article, we have covered six types of bearings and their applications. We hope that you got pure value and knowledge from this article. Thanks for reading this article and don’t forget to share this article maximum!