Definition

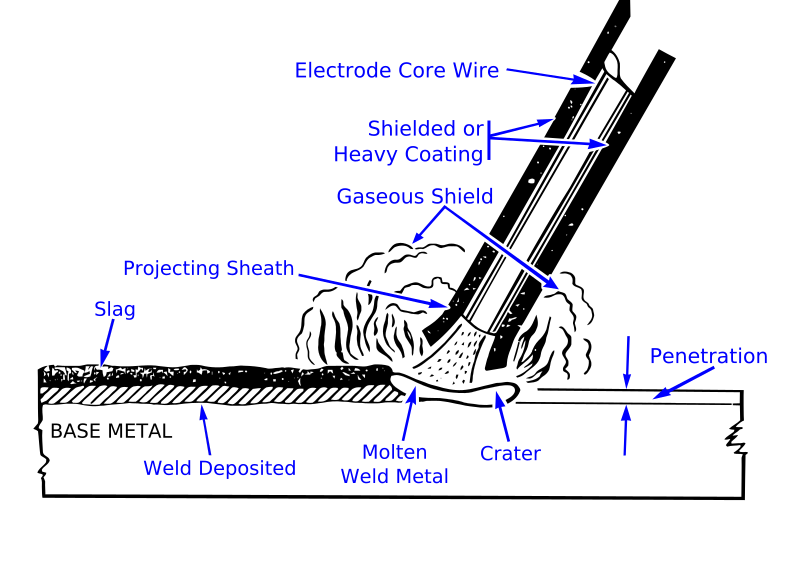

Shielded metal arc welding (SMAW) is a type of arc welding in which a flux-covering electrode is used to join the two metal pieces together. It uses a consumable electrode that has a flux covering on it that gives off shielding gas to protect the weld area from atmospheric contamination and also gives slag deposited on the top of the molten metal weld and protects it too. After welding, the slag is removed by using a chipping hammer and wire brush.

- Since this welding process produces shielded gas to protect the weld pool from atmospheric contamination and that’s why it is called Shielded metal arc welding.

- It is a manual arc welding i.e. it is done by hands.

- The other name of this welding is Manual metal arc welding (MMAW or MMA), Flux shielded arc welding, Stick welding.

History

In the year 1888, Nikolay Slavyanov invented the consumable metal electrode for welding. After that in 1900, the first coated electrode was given by Arthur Percy Strohmenger and Oscar Kjellberg. This is the era of development of the most widely used welding i.e. known as Shielded metal arc welding.

Working Principle SMAW

It works on the principle of heat produced by the electric arc. The heat produced by a consumable flux coated electrode is used to melts the base metal and fuse them together to form a strong weld joint. It uses a flux coated electrode that melts and acts as filler material. It also gives off shielding gas and slag to protect the weld area from atmospheric contamination.

Main Parts Shielded Metal Arc Welding

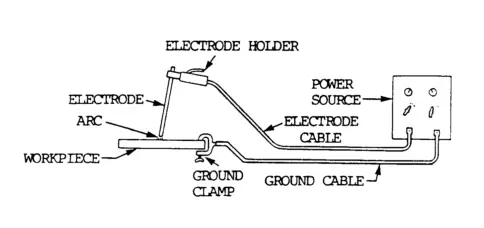

- Power Supply

- Electrode

- Electrode Holder

- Ground Clamp

- Welding cables or leads

Power Supply

A constant current output power supply is used in SMAW process that provides constant ( that does not change) current during welding even in the case the arc distance and voltage changes.

Electrode

Consumable types of electrodes with flux covering is used in SMAW. The electrode gives off vapors known as shielding gas and slag during the welding process. The shielding gas protects the weld area from atmospheric contamination and slag deposited on the molten metal and prevents it to come in contact with atmospheric gas and saves it from oxidation (contamination).

The selection of electrode in SMAW depends upon various factors

1. Material of the weld

2. Welding Position

3. Desired properties of the weld

Electrode Holder

It is used to hold the electrode in the desired position for welding.

Welding Cables or Leads

These are the cables used to connect the electrode and workpiece with the welding power supply. They are also called as leads.

Ground Clamp

It is clamped to the workpiece and another end is connected to the terminal of the welding power supply via welding cables. It completes the circuit and the flow of current starts.

Also Read:

- What is Slotter Machine?

- What is Lathe Machine? Main parts, Operations and Working

- What is Difference Between Soldering and Brazing?

Other safety equipment that is mandatory during Shielded metal arc welding is

Welding Helmets

It is one of the most important equipment for every type of welding. It protects the head, face, and neck area from sparks and radiation produced during welding. If someone initiates the welding process without a good helmet then his skin or eyes get damaged quickly by the powerful radiation (ultraviolet and infrared) produced by the arc.

Mask or Respirator

During the welding process, harmful gases and small metal particles get mixed with air and if it is inhaled directly by the welder, it surely damages the lungs. To protect the lungs from it we use respirators that gets fits easily inside our welding helmets.

Apron or Jacket

Leather jackets are used by a welder for decades. It offers greater protection from heat and sparks produced during the process. Leather jackets have excellent fire resistance and durability in light and heavy-duty welding process.

An apron is also used under the jackets that offer extra protection from the heat.

Welding Gloves

Leather welding gloves are used to protect hands from the heat and spark of the welding. If welding is done without wearing appropriate gloves then heat and spark or molten metal may damage welder’s hands more badly. So it is advised to the welder to wear leather gloves before starting to weld.

Shoes or Boots

Leather Welding shoes are used to provide protection from the heat, sparks, or heavy tools during the welding process. It also protects you fr0m the open wires in the case you put your feet on it and may get a severe electric shock.

Working of Shielded Metal Arc Welding

First, the power supply is on. Now the electrode holder is brought near the gap between the metal two pieces to be joined. Now The electrode tip is gently touched to the base metal piece and then moved apart. This produces an arc and then a small gap is maintained between the electrode and workpiece which results in the continuous arc.

Now the heat of the arc produced melts the metal from the two pieces and it fills in the gap and forms a molten weld pool. The electrode is moved in a zigzag manner during the process. Since the consumable electrode is used here, so it melts and gives of shielding gas and slag. The shielding gas protects the molten weld pool from atmospheric contamination and the slag also covers the molten metal and protects it from contamination by the atmospheric gases.

As the molten weld cools, it forms a strong joint. After that, the slag that is formed on the top of the weld joint is removed by the chipping hammer.

Finally, we have a strong welding joint produced by the SMAW process.

Watch the Video For a better understanding of the SMAW welding process

Safety Precautions in SMAW

Before initiating the shielded metal arc welding process, All the safety equipments like welding helmets, masks, jackets, apron, shoes must be worn by the welder. It ensures the safety of the welder’s life to a greater extent in the case of any mishappening or accidents.

Advantages

- It is a simple welding process and can be done easily without much training.

- It can be used in any position for welding.

Application

Due to its simplicity, it is the most popular welding technique in the world.

- It is most widely used in the maintenance and repair industries.

- In industrial Fabrication, it is used to create metal structure.

- It is used to construct steel structures for construction work.

- It is most commonly used to weld carbon steel, stainless steel, low and high alloy steels, ductile iron, and cast iron. It can also be used for welding nickel, copper, and alloys of both. In some rare cases, it can also weld aluminium.

In this article, you have learned about what is Shielded metal arc welding (SMAW) process, its main parts, working principle, advantages, and application with a video tutorial. If you found this piece of information useful and valuable then don’t forget to like and share it.