Twin Screw Supercharger also works the same as other superchargers and is driven from the engine’s crankshaft via a belt or gear drive. The twin screw name has given because, it uses a pair of spiral rotor which is identical and both are in the shape of a screw. It comes under the positive displacement device and is more efficient than the roots type.

It is used for increasing air quantity in the engine cylinder for more combustion which actually leads to more horsepower and torque from the engine. The air suction and compression process is done in a very unique way whereas, in other devices, just air gets sucked at the inlet side and pushed at the discharge side. It looks similar to roots supercharger

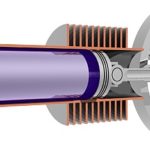

Main Parts of Twin Screw Supercharger

1. Bypass Actuator:

This can control the bypass valve opening and closing action for the intake manifold to provide the required boost level. It is controlled by ECU and it has a boost control shaft and boost control solenoid. At low speed, no boost is required, at that time by pass valve stays open and there is no pressure in the intake manifold. But when high speed high boost is required, the by-pass valve gets closed, which causes the increase of pressure in the intake manifold

Also Read:

2. Housing:

It is the outer body of the device in which spiral rotors are being placed and the assembly of the twin screw supercharger. It is made up of high thermal resistant material made up of cast aluminum. But carbon fibers as a recent material used in housing for less weight and more strength.

3. Front Cover:

The front portion where the input shaft is placed Inside of it and driven pulley fixed at outside. It is in conical shape

4. Drive Pulley:

From the drive pulley, this device gets the rotational power from the engine belt. As the pulley rotates two rotors can try to move in a different direction as per mechanism. It can initiate the further processes for the twin-screw supercharger.

5. Bearings:

Anti-friction ball bearings actually support the backside of both rollers which absorbs the drive loads. After a long usage of the device, the bearing may wear out and causes noise problem.

6. Time Gears:

It has helical gears and must be of high quality with good tolerance to maintain the gap between the rotors. A small inaccuracy in the gear profile makes contact with rotors and also causes the noise.

7. Rotors:

Rotors are spiral in shape and designed in such a way that they never touch each other or housing. Each rotor will get rotational motion in the opposite direction. Both rotors are slightly differing in edges, one looks like a conical taper, and another looks like worm gear.

Also Read:

- How Turbocharger Works – Explained?

- What is Hydraulic Braking System and How It Works?

- Comparison Between Roots, Twin Screw and Centrifugal Supercharger

Working Of Twin Screw Supercharger

- This device starts its function from driving pulley and power transmitted to input shaft that makes the rotors to move in the opposite direction. One of its rotors has taper teeth section and second rotor has warm gear teeth section.

- When both side of rotor pocket meshes together, air gets squeezed between them. When air get start to compress by both side of rotor’s pockets the air flow in auxiliary motion at inlet and transported horizontally all the way to discharge side in radial motion.

- From the discharge side, the compressed air goes to intercooler, here it decreases the high temperature to a desired low temperature and pressurized air goes into the inlet manifold of the engine. At less temperature of the air the density of air will be greater so, more air molecules mean more oxygen to burn more fuel to achieve more power and torque from the engine.

Advantages of Twin Screw Supercharger:

- More horsepower and boost can be achieved as compared to root type supercharger.

- During each rotation, a specific fixed amount of air is trapped and moved to the discharge side where it is compressed

- Produces more horsepower throughout the entire rpm range.

- Less noisy.

Disadvantages:

- Installation is complex.

- Continuously compression and discharge irrespective of boost requirement at low or high speed.

- It also exhibits heating issues but less as compared with the root type.

Application:

Twin screw supercharger used in automobiles to boost engine power. For example, it is mostly used in racing cars.