Who wouldn’t want some little extra power? However, adding power to internal combustion is not an easy task. Can a small device change engine output? Yes, Horsepower can be added up to 40-80%. There is the magic device which is placed upon or beside the engine. You feel big wow! When the engine sounds crazily vroom-vroom at that same time boost can move your vehicle faster from zero to triple digit speed. All the respect to this little device called Centrifugal Supercharger.

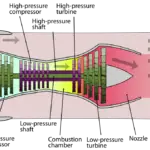

It provides more air density for each intake cycle of the engine. More air means more oxygen to burn more fuel in the combustion chamber. This is very valuable to automobile vehicles for boost and that extra horsepower that is needed for racing. A centrifugal supercharger is looked same as a turbocharger, but this is run by the belt drive or chain drive via the engine’s crankshaft whereas the turbocharger gets its power from exhaust gases. This is widely used compared to positive displacement superchargers.

Working Principle of Centrifugal Supercharger:

As soon as the impeller gets rotational motion via driving pulley which is connected by chain drive or belt drive via a crankshaft. This impeller rotates at very high speed can start sucking the less pressurized and high-velocity air and drawn directly at diffuser. The diffuser is placed inside the housing and fixed with an impeller and which converts this centrifugal force into the high pressure and less velocity having the hot air density transported through an outlet of the housing to the intercooler. The intercooler can decrease the air temperature and cool air having more air molecules and more oxygen sent into the inlet valve of the engine during the suction stroke. More air can burn more fuel to produce huge horsepower from an internal combustion engine.

Also Read:

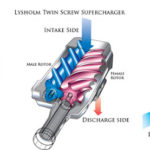

- Types of Supercharger in Automobile

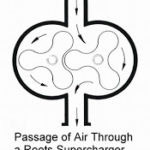

- How Roots Supercharger Works – Easily Explained?

- Twin Screw Supercharger – Main Parts, Working, Advantages, Disadvantages with Application

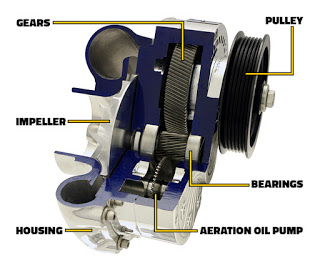

Main Parts of Centrifugal Pump

1. Impeller:

It is a rotating wheel which must be spin at high rpm. It can be removable by scrolling the nut at end of the impeller shaft. Impeller made of steel and composite alloys and machined on CNC milling machine. The impeller speeds can reach up to 100,000 rpm.

2. Diffuser:

It is a stationary wheel having the larger vane compare to an impeller. The impeller sucks the air at high-speed and less pressure. A diffuser converts it to low speed and high-pressure air. This air goes throughout the housing outlet.

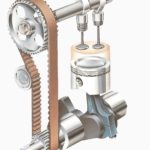

3. Driven Pulley:

Drive pulley is getting the rotational moment from engine crankshaft which has connected via belt or chain with drive pulley of an engine.

4. Bearings:

Ball bearings actually support the rotating shaft which absorbs the drive loads. After a long usage of device, bearing may be worn out and causes noise problem

5. Gears:

Gearing section is large in the centrifugal supercharger. The sun gear is smaller which is surrounded by the mid-size three gears are closed with a ring gear.

6. Transmission:

Planetary gears help to an impeller for achieving greater speed and necessary to produce the desired boost. Sun gear is directly attached to impeller shaft and the ring gear is connected via belt or chain with engine’s crankshaft.

7. Aeration Pump:

Aeration pump placed at below the transmission. It provides self-contained oiling with good bearing lubrication.

8. Housing:

The outer body of the device is called housing. It is made up of aluminum and material has high in strength, weigh less, also corrosion resistance. Housing is manufactured by the casting process and machined such a way that should match the impeller design and size.

Also Read:

- Difference Between Turbocharger and Supercharger

- How Turbocharger Works – Explained?

- How a Car Air Conditioning System Works? – Nicely Explained

Working of Centrifugal Supercharger

- As the engine starts, the supercharger connected to the crankshaft through the belt also starts rotating.

- the impeller of the centrifugal supercharger starts rotating and sucks the high speed and low pressure air from the atmosphere axially. It compresses the air, reduces the speed of the air and gives high density air at its outlet. The pressure increases and velocity decreases as the air moves from impeller blades to the diffuser blade and then finally from the casing.

- The high density and high pressure compressed air is passed to the inlet manifold of the engine.

- This high dense air burnt the fuel in the engine cylinder more efficiently and increases the power of the internal combustion engine to a greater extent.

- The impeller rotates at a speed of upto 100,000 rpm.

Advantages:

- Boost level is high compared to other superchargers (up to 40 psi).

- Less heat generation.

- Small and compact.

- Parasitic load: power required to turn centrifugal supercharger is very less.

Disadvantages:

- Not great for low rpm boost.

- Engine oil is required.

Applications:

Centrifugal superchargers are used in Automotive, Truck, marine, aircraft and Utility vehicles

If you find anything missing in that, then suggest or makes us correct through your valuable comments. And if this article has enhanced your knowledge than don’t forget to share it.