What is Lamont Boiler?

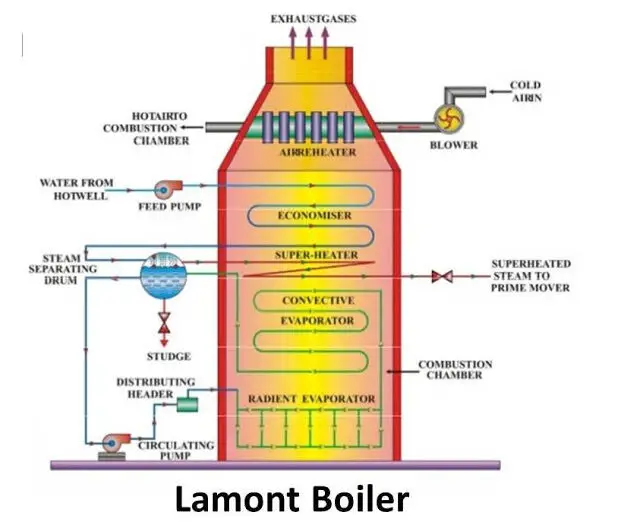

Lamont boiler is a high pressure, forced circulation, water tube boiler with internally fired furnace. An external pump is used to circulate the water within small diameter water tubes of the boiler. This boiler was invented by Walter Douglas La-Mont in the year 1925. At that time this boiler was invented to use in ships.

Working Principle

It works on the principle of forced circulation of water within the boiler with the help of centrifugal pump. Its working is totally depends upon the pump. The centrifugal pump circulates the mixture of steam and water through the small diameter tubes of the boiler.

Main Parts or Construction

The main parts of the Lamont boiler are:

1. Feed pump:

It supplies the feed water into the boiler from the hot well.

2. Economizer:

It increases the temperature of the feed water to some degree.

3. Steam Separating Drum:

As its names indicates, the steam separating drum separates the steam form the water. The steam gets collected at the upper portion and water at the lower portion of the drum.

4. Circulating Pump:

It is a centrifugal pump driven by the turbine. It circulates the water from the steam separating drum to the small diameter tubes of the radiant superheater, convective superheater, and back to the steam separating drum.

5. Radiant Evaporator:

It evaporates the water steam mixtures with the help of radiation.

6. Convective Evaporator:

It changes the mixtures of steam and water into saturated steam through convective mode of heat transfer.

7. Superheater:

It superheats the steam to the desired temperature for striking on the turbine blades.

Also Read:

- Difference Between Fire Tube Boiler and Water Tube Boiler

- Cochran Boiler – Main Parts, Working, Advantages and Disadvantages

- Lancashire Boiler Construction, Working with Diagram

Working of Lamont Boiler

- In Lamont boiler, the feed pump circulates the water in the economiser of the boiler. The economiser heats the water to some degree. From economiser, water enters into steam separating drum.

- From steam separating drum the mixture of water and steam is forced circulated through the radiant evaporator by an external centrifugal pump. In forced circulation, the pressure of circulation of water through the tubes is more as compared with the natural circulation.

- Radiant evaporator heats the water and changes it into steam. Form radiant evaporator the water-steam mixture passes through the convective evaporator. Here the temperature of the fluid increase and most the water gets converted into saturated steam. And after that the saturated steam enters into the steam separator drum.

- The steam separator drum as names indicate separates the steam from water. The steam gets collected at the upper portion of the drum. From the steam separator drum, steam passes through the superheater. The superheater increases the temperature of the steam to the desired level. And finally, the superheated steam is either transfer to the steam collecting drum or made to strike on the blades of the turbine.

- The working pressure, temperature, and capacity of this boiler is 170 bar, 773 K and 50 tonnes/h.

Advantages

- It can be easily started.

- High steam generating capacity (about 50 tonnes per hour)

- It has high heat transfer rate.

- This boiler can be reassembled with the natural circulation boilers.

- Its design is simple.

Disadvantages

There is a bubble formation at surfaces of the tubes in this boiler. This reduces the heat transfer rate to the steam.

Conclusion

Here we have studied about What is Lamont Boiler, its main parts, working, advantages and disadvantages with diagram. I hope this article has cleared your doubt about this boiler. If you found this piece of information useful and valuable then don’t forget to like and share it.