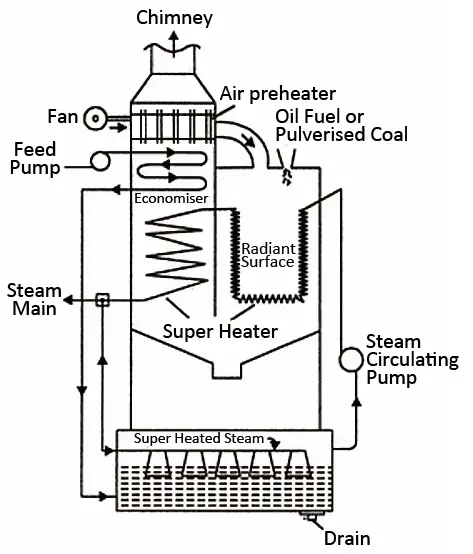

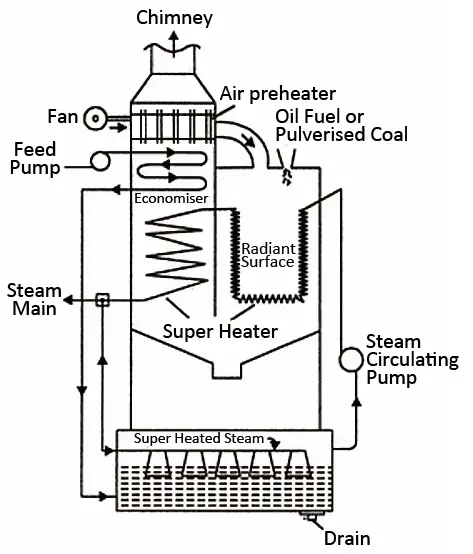

Loeffler Boiler is a forced circulation, high pressure, and water tube boiler with an internally fired furnace. In this boiler, the 2/3 of superheated steam is used to evaporate the water in the evaporating drum, and the remaining 1/3 of the steam from the superheater is used by the turbine. A steam circulating pump is used to circulate the steam into the boiler.

Working Principle

Its main working principle is to evaporate the feed water by the use of superheated steam from the superheater. 2/3 of the total steam generated by the superheater is made to flow into the evaporator drum. The superheated steam changes the feed water into saturated steam. And 1/3 part of the superheated steam is used by the turbine to do work.

Also Read:

- Lamont Boiler – Main Parts, Working, Advantages and Disadvantages

- Cochran Boiler – Main Parts, Working, Advantages and Disadvantages

- Babcock and Wilcox Boiler – Construction, Working, Application, Advantages and Disadvantages

Main Parts

The main parts of the Loeffler boiler are

- Feed Pump

- Economiser

- Evaporating Drum

- Steam Circulating Pump

- Radiant Superheater

- Convective Superheater

- Mixing Nozzle

1. Feed Pump:

The feed pump is used to feed water into the boiler that is used to generate steam for the turbine.

2. Economiser:

The economiser preheats the feed water before entering into the evaporating drum.

3. Evaporating Drum:

It is placed at the lower portion of the boiler. It contains the mixing nozzle. Here the feed water is converted into saturated steam with the help of the superheated steam from the superheater.

4. Steam Circulating Pump:

It is present in between the evaporating drum and radiant superheater. It circulates the steam into the boiler.

5. Radiant Superheater:

It superheats the steam with the help of radiations produced by the burnt fuel in the boiler.

6. Convective Superheater:

Convective superheater superheats the steam to the desired temperature of about 500 degree C.

7. Mixing Nozzle:

It is present inside the evaporating drum. It mixes the steam from the superheater with feed water and evaporates them.

Also Read:

- Locomotive Boiler – Construction Working and Application

- Scotch Marine Boiler Construction, Working, Advantages with Diagram

- Benson Boiler – Construction, Working Principle and Advantages with Diagram

Working of Loeffler Boiler

- In the Loeffler boiler, the feed pump forces the water to enter into the economiser. The economiser preheats the feed water and then it is passed to the evaporator drum.

- The evaporator drum has nozzles. The 2/3 of the superheated steam from the superheater enters into the nozzles of the evaporator drum and the nozzles mix this superheated steam with the feed water. This changes the feed water into saturated steam. This saturated steam is then drawn from the evaporating drum by a steam circulating pump and allows it to pass through the radiant superheater.

- The radiant superheater superheats the saturated steam with the help of radiation energy produced from the burning of the fuel. The radiant superheater tubes are placed in the furnace. The heat transfer to the water takes place through the radiation produced. After the radiant superheater, the steam is passed to the convective superheater.

- The convective superheater is placed in the path of hot flue gases. It superheats the steam coming from the radiant superheater to a temperature of about 500 degree C. This superheated steam then flows to the turbine and evaporating drum. In this boiler, the 2/3 part of the superheated steam is used to evaporate the feed water into the evaporating drum and the remaining 1/3 part flows to the turbine.

- Loeffler boiler has the capacity to produce 100 tonnes/ h of steam at a temperature of 500 degree C and pressure of 140 bar.

Advantages

- It can use salt water for steam generation.

- The problem of deposition of sediments and scale in the boiler tubes are eliminated.

- It is compact in size.