What is a Cochran Boiler?

Cochran Boiler is a vertical drum axis, natural circulation, natural draft, low pressure, multi-tubular, solid fuel fired, fire tube boiler with internally fired furnace. It is the modified form of a simple vertical boiler. In this boiler, the fire tubes are placed horizontally. The efficiency of this boiler is much better than the simple vertical boiler. The main function of the cochran boiler is to produce steam for the generation of electricity. The steam produced is transferred to the steam turbine where electricity is generated.

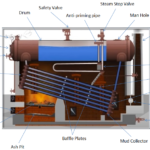

Main Parts and Construction

1. Shell:

It has a vertical axis cylindrical drum with a hemispherical dome-type shell at the top.

2. Grate:

It is the platform on which the solid fuel is burnt.

3. Combustion Chamber:

The burning of fuel takes place in the combustion chamber.

4. Fire Tubes:

Cochran boiler has multi-tubular fire tubes. The hot flue gases from the combustion chamber travels to the smokebox through these fire tubes. The fire tubes helps in the exchange of heat from the hot flue gases to the water.

5. Fire Hole:

It is the hole provided to fire the fuel inside the furnace.

6. Furnace:

It lies at the bottom of the boiler. Furnace is the place where all the fuel is burnt. Without furnace, the working of this boiler is not possible.

7. Chimney:

The chimney is attached to the smokebox. It transfer smoke to the environment. The size of the chimney is small as compared with other boiler.

8. Fire Brick Lining.

The fire brick lining is present in the combustion chamber and helps in the combustion of the fuel.

9. Manhole:

A manhole is provided for the cleaning and inspecting of the boiler from inside.

10. Flue Pipe:

It is a small passage connecting the firebox and combustion chamber. The hot gases enter into the combustion chamber through the flue pipe.

Other Boiler mountings and accessories attached to the this boiler are:

1. Pressure Gauge: It measures the pressure of steam inside the boiler.

2. Safety Valve: It blows off the extra steam when the steam pressure inside the boiler reaches above safety level.

3. Water level Indicator: The position of the water level in the Cochran boiler is indicated by the water level indicator.

4. Stop Valve: Stop valve is used to transfer steam to the desired location when it is required. Otherwise, it stops the steam in the boiler.

5. Blow off Valve: It is used to blow off the settle down impurities, mud and sediments present in the boiler water.

Also Read:

- Babcock and Wilcox Boiler – Construction, Working, Application, Advantages and Disadvantages

- Locomotive Boiler – Construction Working and Application with Diagram

- Benson Boiler – Construction, Working Principle and Advantages with Diagram

Working of Cochran Boiler

- In Cochran boiler first the fuel is inserted into the firebox and placed on the grate. The fuel is ignited through the fire hole provided at the right bottom of the boiler.

- The fuel is burnt in the firebox, and due to the burning of the fuel, smoke and hot flue gases emerge out. The hot flue gases enter into the combustion chamber through flue pipes.

- From the combustion chamber, hot gases enter into the fire tubes. The fire tubes are surrounded by water. The hot flue gases inside the tubes exchange the heat from the hot gases to the water. Due to the exchange of heat, the temperature of the water starts increasing and it gets converted into steam. The steam produced rises upward and collected at top of the boiler in the hemispherical dome. An anti-priming pipe is installed at top of the boiler which separates the water from the steam and makes it dry steam. This dry steam is then transferred to the turbines through the steam stop valve.

- The hot flue gases and smoke after exchanging heat moves to the smokebox. From the smokebox, the burnt gases and smoke is discharged to the atmosphere through the chimney.

- Burnt fuel is transferred to the ash pit. Blow off Valve is preset at left bottom of the boiler and is used to blow off the impurities, mud, and sediment from the boiler water.

- A fusible plug is also provided at the top of the combustion chamber. When the temperature of the combustion chamber crosses the permissible level, the fusible plug melts and the water through the combustion chamber enters into the furnace of the boiler and stops the fire. In this way, a big fire accident can be prevented to take place and also protects the boiler from damage.

- Various boiler mounting and accessories are attached to the boiler for its efficient working.

Advantages

- Low initial installation cost.

- It requires less floor area.

- Easy to operate and handle.

- Transportation of Cochran boiler is easy.

- It can use all types of fuel.

Disadvantages

- Low rate of steam generation.

- Inspection and maintenance is difficult.

- High room head is required for its installation due to the vertical design.

- It has limited pressure range.

Conclusion

Here, we have learned about what is cochran boiler, its main parts, working, advantages and disadvantages. I hope you have understood it clearly and if you find this peice of information valuable and useful then don’t forget to like and share it.