AI significantly enhances heavy equipment efficiency by optimizing operations and reducing downtime. Predictive maintenance and real-time data monitoring are key benefits.

The advent of artificial intelligence (AI) has revolutionized the heavy equipment industry, ushering in a new era of efficiency and productivity.

AI-driven technology equips machinery with smart, data-processing capabilities, enabling precise control and automation that were once unimaginable.

By leveraging AI, companies can now monitor equipment performance in real-time, anticipate maintenance needs before breakdowns occur, and make informed decisions that improve operational workflow.

This modern approach to managing heavy equipment not only maximizes uptime but also extends the lifespan of machinery, ensuring that every piece of equipment delivers the best possible return on investment.

As the industry continues to evolve, embracing AI technologies is paramount for businesses aiming to stay competitive and reduce operating costs.

Revolutionizing the Heavy Equipment Industry

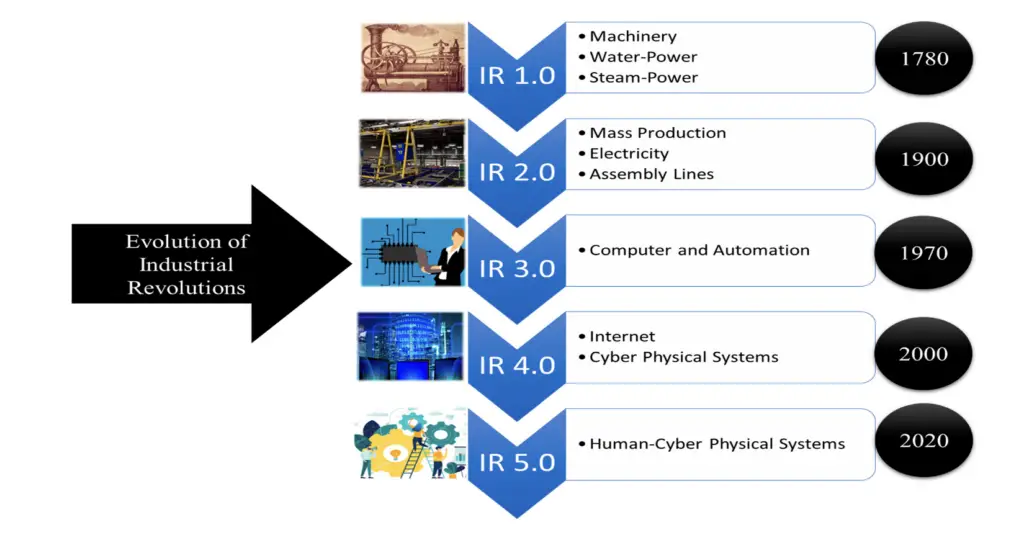

Revolutionizing the Heavy Equipment Industry is a journey that stretches from steam-powered engines to the pinnacle of innovation with artificial intelligence (AI).

Today, heavy equipment for sale is smarter, faster, and eco-friendly thanks to the wonders of AI technology. This intelligent machinery is now changing the game in construction, mining, and agriculture.

Incorporation Of AI Technologies

AI technologies have made it into the heart of heavy equipment sectors. Sensors, data analytics, and smart operations systems are now core features in sophisticated machines.

They enable machines to perform complex tasks with precision and minimal human intervention.

- Machine Learning: Machines now learn from their environment, adjusting operations to become more efficient.

- Automated Controls: Self-driving tractors and earthmovers transform job sites, reducing the need for manual operation.

- Predictive Maintenance: AI predicts equipment failure, saving costs and preventing downtime.

Benefits Of AI in Heavy Equipment

The infusion of AI into heavy equipment brings a plethora of benefits:

| Enhancement | Outcome |

| Operational Efficiency | Machines work faster and with more precision, aiding in project completion ahead of schedule. |

| Safety | AI reduces the risk of accidents, ensuring the safety of equipment operators. |

| Cost Reduction | Fewer errors and predictive maintenance diminish additional costs. |

| Environmental Impact | Lower emissions through optimized fuel usage and efficiency lead to a greener operation. |

Enhanced Performance And Predictive Maintenance

The advent of AI has transformed the landscape of heavy machinery. Heavy equipment for sale today comes equipped with advanced features

to boost performance. Key to this transformation is predictive maintenance, a proactive approach that prevents downtime and extends equipment lifespan.

Real-time Monitoring And Data Analysis

AI systems within heavy equipment enable continuous monitoring. Operators receive valuable insights regarding machine health. These insights help manage equipment efficiently.

AI tracks patterns and pinpoints areas needing attention.

- Engine performance data signals when service is due.

- Vibration analysis can indicate misalignments or imbalances.

- Fuel consumption data help optimize operation costs.

Proactive Maintenance Strategies

AI-driven predictive maintenance anticipates potential issues. This approach schedules repairs before breakdowns occur. It balances operation continuity with optimal maintenance. Proactive strategies involve:

| Strategy | Benefits |

| Condition-based alerts | Reduces unscheduled stops |

| Automated service reminders | Keeps maintenance on track |

| Life-cycle analysis | Enhances component longevity |

Effectively, AI not only enhances the efficiency of heavy machinery but also ensures they are ready for sale with fewer issues for the new owners. A win-win for both sellers and buyers in the market for heavy equipment for sale.

Optimizing Operations And Safety

The integration of AI into heavy equipment has revolutionized the industry. Operations once deemed complex now achieve new efficiency levels.

Safety, once a major concern, sees substantial enhancement. AI doesn’t just streamline processes; it protects lives. Let’s dive into how AI optimizes operations and invigorates safety protocols.

Autonomous Vehicles And Machinery

Self-driving technology extends beyond passenger cars. Heavy equipment industries now leverage AI for autonomous operations.

This technology minimizes human error, aligns with precision, and cuts down operation time.

- Enhanced productivity results from machines that operate tirelessly.

- Error reduction comes from precise AI calculations and movements.

- Remote monitoring allows operators to manage equipment from a distance.

Intelligent programming enables machines to adapt to diverse environments. From mining to construction, autonomous heavy equipment is changing the landscape of work for the better.

Enhanced Safety Protocols

With AI, safety measures in heavy equipment operations reach new heights. AI’s predictive capabilities spot potential issues before they pose a risk. Safety systems step in promptly, ensuring worker protection.

| Feature | Benefit |

| Proximity Alerts | Prevent collisions before they occur. |

| Automated Shutdown | Initiate protective measures in risky situations. |

| Health Monitoring | Track equipment status to avoid malfunctions. |

In the realm of heavy machinery, AI doesn’t just protect assets; it safeguards operators. By integrating AI, businesses ensure both their people and machines can operate in a safer, smarter world.

Challenges And Future Outlook

The journey of integrating AI into heavy equipment manages both promise and complexity. Today’s market, bustling with Heavy Equipment for Sale, is on the brink of a revolution.

This revolution boasts increased efficiency and productivity. Yet, it faces its share of obstacles.

Adoption Hurdles And Training Needs

The road to AI adoption within the heavy equipment sector isn’t without its bumps. Organizations must navigate these challenges:

- High Investment Costs: Initial expenses can deter companies.

- Integration Complexities: Merging AI with existing systems requires expert skill.

- Reluctance to Change: Overcoming operational inertia is crucial for progress.

Continuous training forms the backbone of adopting AI:

- Equip teams with the necessary skills.

- Ensure ongoing learning matches AI advancements.

Future Trends In AI for Heavy Equipment

The horizon for AI in heavy equipment shines bright. Here’s what to expect:

| AI Trend | Expected Impact |

| Predictive Maintenance | Reduce downtime, and save on repair costs. |

| Autonomous Operation | Increase safety, and enhance precision. |

| Smart Analytics | Improve decision-making, and optimize performance. |

Bolder AI applications will surface as technology evolves. Smart heavy machines will keep setting trends.

They’re reshaping future job sites, leading to more informed choices in the Heavy Equipment for Sale market.

Frequently Asked Questions For AI in Heavy Equipment Efficiency

How Ai Is Useful In Heavy Industry?

AI enhances efficiency in heavy industry by optimizing operations, reducing downtime, and improving safety with predictive maintenance and real-time monitoring.

It also streamlines the supply chain and aids in making data-driven decisions for increased productivity.

How The Use Of AI Can Help Improve The Safety And Efficiency Of The Factory?

AI enhances factory safety by predicting equipment failures and scheduling proactive maintenance. It boosts efficiency by optimizing production workflows and reducing downtime.

How Does AI Improve Business Efficiency?

AI streamlines workflows automates routine tasks, and enhances data analysis for informed decision-making, boosting business productivity and efficiency.

How Can AI Impact The Construction Industry?

AI enhances construction industry efficiency through predictive analytics, risk assessment, and automated project management.

It boosts safety via real-time monitoring and fosters design innovation with advanced simulation capabilities.

Conclusion

The future of heavy machinery looks brighter with AI. Enhanced efficiency and safety are just the start; predictive maintenance and operational insights promise transformative shifts.

Adopting AI is no longer a trend but a necessity for progress. Embrace the innovative stride, and let’s watch industries evolve with intelligent automation.