As businesses strive for optimal operation efficiency, finding effective solutions for storing sheet materials is crucial. Whether your warehouse needs to store metal, plastic, or any other materials vital to your operations. The need for an efficient solution that not only maximizes space but also allows for easy retrieval becomes essential.

In this context, roll out sheet racks emerge as the key players in enhancing efficiency, organization, and overall productivity. Read on to find out more about this ingenious storage racking system favoured by many warehouses.

Understanding the Need for Heavy Duty Storage Solutions

Warehouses handling heavy materials often face storage problems that can impact both efficiency and safety. Improper storage can lead to damaged materials, inefficient retrieval processes, and even pose safety risks for warehouse staff. Investing in specialized storage solutions addresses these challenges, providing a dedicated and organized solution for your materials.

Roll out sheet racks are a great example of heavy-duty sheet metal storage racks. These storage solutions can help warehouses optimize their floor space while keeping materials easily accessible.

Key Features to Look For in Roll out Sheet Racks

When selecting roll out sheet racks, it’s crucial to consider 3 key features. These are load capacity, the ability to adapt, and the durability. Taking these aspects into account will help you select storage solutions that can cater to your specific needs. This ensures seamless integration into your existing warehouse.

Knowing the load capacity of a roll-out sheet rack ensures that it can handle the weight of the items you intend to store. This prevents overloading, which can lead to structural damage and safety hazards. Although load capacities vary from model to model, some of the sturdiest roll out sheet racks have a drawer capacity of 5,000 pounds.

Also Read:

- How Is Technology Revolutionizing the Manufacturing Industry?

- 3D Printing Enables Flexible Automotive Manufacturing to Meet Market Demands

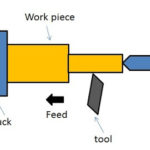

- Types of Lathe Machine – Mother of all Machines

Additionally, the ability to adapt allows you to adjust to changing business needs. This flexibility is crucial in a dynamic warehouse environment where inventory needs may change over time. They allow you to adapt to changes without needing to invest in entirely new storage solutions.

Furthermore, durable roll out sheet racks can withstand the demands of daily warehouse use. While their initial cost is higher, their increased longevity often results in long-term savings. Indeed, robust shelving solutions require less frequent replacement or maintenance and have a longer lifespan.

What’s more, load capacity, the ability to adapt and durability is all directly linked to safety. Choosing the right storage solution can help reduce the risk of racking falling or collapsing. Thereby reducing the risk of accidents in the warehouse. This is crucial for the safety of your employees and the protection of your inventory.

Best Practices for Installing and Using Roll Out Sheet Racks

To make the most of your storage systems, follow these best practices:

- Ensure proper installation by trained professionals.

- Regularly inspect and do maintenance to prevent wear and tear.

- Prioritize safety through clear labelling and training for warehouse staff.

Adhering to these best practices contributes to the overall safety, efficiency, and longevity of roll out sheet storage racks. It helps create a secure working area and lowers the risk of accidents. It also ensures that the racks are used efficiently to meet your warehouse operations needs.

The choice of racking systems has an impact on the efficiency of your warehouse operations. For many warehouses, investing in roll out sheet storage racks is more than just a purchase. It’s a strategic move to improve warehouse efficiency. Indeed, they can help your warehouse improve its storage capacity, while contributing to a safer, more organized workspace.

Your business can take the first step toward operational efficiency by investing in the right storage solution. Ensure your company’s long-term success by helping it achieve a smooth, streamlined operational workflow. Go beyond traditional storage options. Provide your warehouse with a storage solution that aligns with the dynamic demands of today’s market.