Many businesses often need a CNC machining service due to a wide variety of reasons. Sometimes a business needs to do grinding and planting, and sometimes they need to create prototypes.

Even though a machining service can help with all of that, more than a few things could not go according to the plan if a company fails to pick a reliable machining service. And since a project may be at stake in this situation, these failures need to be avoided at all costs.

So, let’s take a look at what factors you need to check before agreeing on terms with a company for your next CNC machining services. If you need these services for surface grinding, milling, or turning, this information will help you choose the best option.

What is CNC machining and what are its applications?

CNC machining is a broad term used for numerous machining applications. Basically, CNC stands for Computer Numerical Control, and it indicates that the machine has a programmable feature that allows it to perform many functions with minimal human control.

Let’s go through some of the most common types of precision CNC machining:

- CNC lathes, as well as turning machines, are characterized by their ability to rotate (turn) materials on an axis during the machining operation. The cutting tools for these machines are fed in a linear motion along with the rotating bar stock.

- CNC milling machines have the ability to rotate the cutting tools and hold the material workpiece/block stationary at the same time.

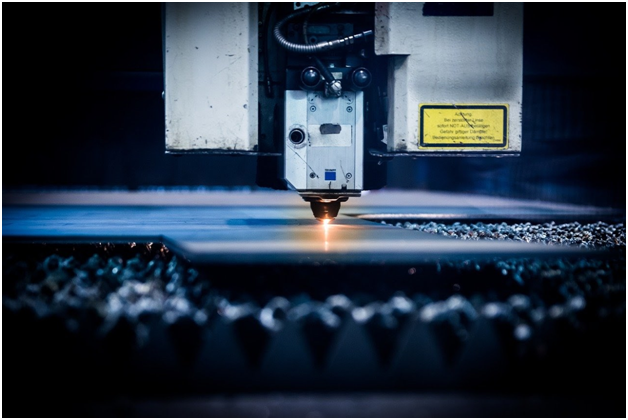

- CNC laser machines have a pointed router that has a highly focused laser beam; they are used to precisely engrave, slice, or cut materials.

- CNC electrical discharge machines (EDM) utilize highly controlled electrical sparks to manipulate materials to form the desired shape. This action is also called spark eroding, die sinking, spark machining or wire burning.

- CNC plasma cutting machines are used to cut materials, but they perform this action using a high-powered plasma torch that is controlled by a computer.

Factor 1: Business usage and needs

This should be one of your top priorities when looking for machining services for your business. First, you need to consider your business needs and then start looking for machining services.

Ask yourself why you need this service and remember that there is a wide range of reasons why you may need to do it.

Here are some of the major functions that decent machining companies usually offer:

- Turning

- Milling

- Grinding

- Plating

- Prototyping

- Surface finishing

It’s important to first find the purpose for the service you are seeking before you actually reach out to any business.

Factor 2: Production capacity

This is most likely the factor that matters the most following your business needs and usage requirements.

Once you determine the needs, you need to find out the production capacity of each CNC machining service provider that you have shortlisted. In simpler terms, this usually refers to the size of the facility, the number of machines the service operates, as well as the number of skilled technicians the company has employed.

When you figure this out, you will get a feeling of what you need regarding the scale of the operation, and that will allow you to find out if the CNC machining service can handle your project coupled with the work of its other clients.

Factor 3: Determine your budget

This is another important factor that you need to consider when choosing the right machining service provider for your project.

It is easy to spend through the roof on a CNC machining service and still fail to satisfy all your project needs. But with a good budget plan and the right knowledge, you can pick a service that offers everything your business might need while remaining within your budgetary capabilities.

Keep in mind that the machine prices of VMC (vertical machining center) compared to HMC (horizontal machining center) machines are lower. Therefore, hiring them could help you get a better price.

Remember that the cost difference should not be a single condition. Before you hire a service and sign the papers, make sure that the respective service offers you the pertinent services for your machining needs.

Factor 4: Precision and flexibility

When it comes to the success of a project, it is vital to denote that manufacturing with precision is of the utmost importance. That is why you need to make sure that your CNC service provider takes good care of every single detail.

These include but are not exclusive to:

- Size

- Shape

- Dimension

- Needed materials

Moreover, this plays an important role in a few other segments other than just designing products precisely.

Bear in mind that it is also essential that you use raw materials efficiently with a low wastage in order to reduce the excess cost to the company. Therefore, try to go for a CNC service provider who will efficiently manage the raw materials and product designing on their own.

On top of that, a good CNC machining service provider also has to work closely with you and quickly adapt to the changes that you recommend.

The business you select needs to be as flexible as the product manufacturing industry itself. They need to understand changes in the product requested by you, and they should also implement them in a timely fashion so that you don’t have to worry about your deadlines.

Factor 5: Location

This is yet another important factor that you need to consider once you start choosing your CNC machining service company. Its geographical location matters and you need to know how close it is to your own business. Having a nearby CNC service provider considerably reduces logistics costs and makes it easier to communicate quickly and precisely.

Of course, as the internet allows for worldwide communication, you can also choose your service provider from different corners of the world. However, it’s much better to choose a good CNC company within your local area as it reduces the risk of product damages during transportation. And you won’t have to worry about extra fees or other legal issues.

Final thoughts

Hopefully, you are now familiar with the basics of CNC machining. This content piece should be enough to steer you in the right direction regarding the service provider you want to select.

Again, it is important to consider these factors since they are really important in the whole process. So, take another good look and make sure you have these factors in mind when you start picking your next CNC service provider.

Image Sources

- By Michal Jarmoluk from Pixabay