Introduction

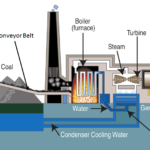

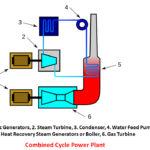

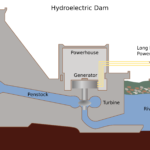

The power stations like a steam power plant where a large amount of exhaust steam is generated by the steam turbines are passed into the condensers where the exhaust steam gets converted into hot water. Now the cold water that is used by the condensers to cool the exhaust steam is supplied by the cooling towers. The main purpose of the cooling towers is to extract the heat from the hot water and makes it cool for recirculation in the condenser. The Cooling towers are used where a large cooling effect is required such us in large factories, power stations, etc. Here in this article, we will discuss cooling towers, its working principle, main parts, types, benefits and area of application in detail. So let’s begin our study from its definition.

What is a Cooling Tower?

These are the towers in the cylindrical shape having a narrow cross-section area in the middle that is used to cool hot water from the power stations, industries. etc. They are very large in size and has large efficiency of cooling. It is also defined as a device used to remove heat from the hot water.

Working Principle

The cooling towers work on the principle of evaporative cooling. The air when comes in the contact with the hot water, It takes the latent heat of the water and makes it cool. Also after taking the heat from the hot water, the temperature of the air increases and it makes some of the water evaporate and it further cools the water to lower temperature.

Main Parts or Construction Details

The cooling tower parts are as follows

1. Basin:

A basin is made at the bottom of the cooling tower for the collection of the cold water from where it is again circulated to the condensers or industrial equipment.

2. Fills (Heat Exchange Surface):

It is a heat exchanging surface where water and air come in contact with each other and the exchange of heat between them takes place. The surface of the fill is of hexagonal shape that allows maximum surface for the cooling.

3. Nozzles:

Nozzles are attached to the hot water pipe and it sprays water on the fills for the cooling. Nozzles are used to spay water that helps to spread water to a large area and enhances cooling effect.

4. Drift Eliminator:

At the top i.e above hot water pipe, we have drift eliminator. It traps the large droplets of vapor from escaping and minimizes the loss of water from the cooling towers.

Also Read:

- Solar Power Plant – Main Components, Working, Advantages and Disadvantages

- What is a Boiler? Different Types of Boiler

- How Geothermal Power Plant Works – Explained?

Cooling Tower Working

- The hot water from the power plants or industries is spread on the fills (heat exchanging surface) through the nozzles attached to the hot water pipe.

- The fills have hexagonal cavities on it that allow the spread water moves slowly downward. And the air from the bottom of the cooling tower moves upward and passes through the fills. When the air and hot water come in contact with each other, the air takes latent heat from the water and makes it cool. The air has taken heat from the water so it becomes hot and due to this it also evaporates some of the water and further cools the water. As we all know that evaporation gives cooling effect i.e where evaporation occurs the surfaces from where the evaporation is happening gets cooled.

- After cooling the hot water the air moves upward with vaporizing water. Above the hot water pipe, we have drift eliminator. The drift eliminator cools down most of the water vapor and prevents it from escaping the cooling tower. Some of the water vapor that is very less can escapes out. The hot air crosses the drift eliminator and escapes the cooling tower. Some of you might think why this drift eliminator is there, so I will tell you, this eliminator is there for minimizing the loss of water from the cooling tower.

- As the water moves downward through the fills it gets cooler and cooler and finally, it gets collected in the basin. And from the basin, the cold water is again circulated to the condensers of the power plant and industrial machinery for cooling purposes.

- The circulation of the water inside and outside the cooling tower is done by using centrifugal pumps.

Types of Cooling Tower

On the basis of the type of draft and direction of water and airflow through the cooling towers, it is classified as

On the basis of the type of Draft

1. Natural Draft

2. Mechanical Draft: It is again of two types

- Forced Draft

- Induced Draft

On the Basis of the direction of water and airflow

- Cross Flow

- Counter Flow

Let’s Discuss each of them in Detail.

1. Natural Draft Cooling Tower

It is the simplest types of cooling tower in which the airflow takes place naturally without the use of any external agency like fan, blower etc. It consists of basin for the cold water storage, fills for the heat exchanging, nozzles for the spraying water on the fills, drift eliminator to prevent the loss of water.

The working of the natural draft cooling tower is the same as we have discussed above. These cooling towers are used in power plants such as in steam power plants, nuclear power plants or industries where infinite cooling of hot water is required.

2. Mechanical Draft Cooling Towers

In this cooling tower, a mechanical source (Fan or blower) is used to circulate the air inside the tower. The rest of the parts are similar to the natural draft. The propellor fans or centrifugal fans are the common types of fans used in mechanical draft towers. They can be further classified as Forced Draft and Induced Draft.

(i) Forced Draft Cooling Tower

In this tower, fans are there at the bottom side to force the air inside the tower. The air forced moves in the upward direction and makes the hot water cool.

(ii) Induced Draft Cooling Tower

In this tower, a fan is installed at the top of the tower that sucks the air. The air is sucked from the openings at the bottom. The fan induces air inside the tower for cooling hot water.

Working

The working of this cooling tower is similar to that of the natural draft but the difference is that the air is forced or induced into the tower with the help of fans.

Advantages

- As compared to natural draft cooling towers, they are more effective.

- The cooling rate is higher in these towers.

- these towers are small in size than natural draft towers.

Disadvantages

- The power consumption is more and the cost of operation is also high.

Also Read:

- What is Lathe Machine? Main parts, Operations and Working

- Water Jet Machining – Working Principle, Advantages and Disadvantages with Application

- What is Slotter Machine?

3. Counter Flow Cooling Tower

In counter-flow Towers, the air and water move opposite to each other. The water moves in a downward direction and the air in an upward direction. These cooling towers may of Natural Draft type of Mechanical Draft type.

4. Cross Flow Cooling Tower

In Cross flow towers, the air and water move at right angles to each other i.e. they cross each other at a right angle when passing through the fills.In other words, the water flows vertically downward through the fills and the water flows horizontally to the fills. They may of Natural draft type or mechanical draft type. The CT shown above is of induced draft type cross flow.

Difference Between Counter flow and Cross Flow Cooling Towers

| Parameters | Counter Flow | Cross Flow |

| Water and Air Flow | Hot water and air in counter flow cooling tower move horizontally to each other while passing through the fills. | Hot water and air move at right angles to each other when flow through the fills. |

| Types | It may be of Natural Draft Type or Mechanical Drat type (Forced or Induced) | It may also be of Natural Draft or Mechanical Draft Type. |

| Hot water Distribution | The pressurized hot water distribution system is used since the air moves against the nozzle spray. | Non Pressurised hot water distribution system is used because the air does not move against the nozzle. Air has a separate path to flow after passing across the fills. The hot water is allowed to pass through the fills under the effect of Gravity. |

Application of Cooling Towers

- The cooling towers are used to cools the hot water from the power plants ( Nuclear power plant, Steam power plants, etc) and Industrial Equipments.

- It is used in HVAC ( Heat Ventilated Air Conditioning) System for cooling hot water.

Summary

Cooling towers are big structures that are used to cool hot water from power stations and industrial equipment. They are classified as Natural Draft, Mechanical Draft, Forced Draft, Induced Draft, Counter Flow and Cross flow types.

Conclusion

In this article, we have discussed What is cooling towers, its main parts, working principle, types and application with a comprehensive diagram. I hope this piece of information has cleared most of your doubts about cooling Towers. If you like it then don’t forget to like and share.