Introduction

Modification in a component keep occurring until the ideal or near to ideal state of the component is not achieved so with this thought in mind engineers keep on researching on manual transmission to get the best out of it, which leads the researchers from the General Motors to the development of synchromesh gearbox or transmission system in 1928, this system overcame the limitations of later transmission system and gave the answers to all the transmission related question, let’s find more about it.

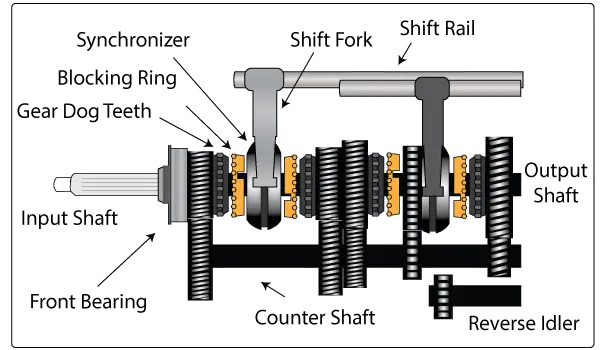

Synchromesh gearbox or transmission system is a type of transmission system in which the dog clutches from the constant mesh gearbox is replaced with the special shifting devices known as synchromesh devices which makes the system compact and also provide smooth and noise free shifting of gears.

In synchromesh transmission the pair of gears which has to be used for final transmission of output first bring in frictional contact with the synchromesh device and then final selection of the appropriate gear takes place.

It usually comes with the 5-speed 1-reverse manual transmission configuration for example- Maruti Suzuki swift.

With suitable modification in shifting lever mechanism synchromesh gearbox is also used in racing cars like formula-1, because of its quick and smooth response.

Why Do We Need Synchromesh Gearbox?

Since, the introduction of the transmission system from sliding mesh to constant mesh various modification is made in both the systems to make them smooth, less noisy and to make the shifting response quick, though the constant mesh overcame the important limitations of sliding mesh gearbox like double-de-clutching, wear and tear but still has its own limitations, let’s discuss them:

- The response to the shifting of gears in the constant mesh gearbox is not quick as the dog clutches used in constant mesh gearbox has to mesh with the rotating pair of gears which is not a quick task.

- There is a lack of a mechanism in constant mesh gearbox that can bring all the rotating shafts that are clutch shaft, main shaft and lay shaft at the same rotating speed, which is responsible for the harsh shifting.

- The teethes of the dog clutches shows wear and tear which in turn increases the maintenance of the system.

- The shifting in constant mesh gearbox is a noisy process as the dog clutches has to make contact with rotating gear pair.

- The constant mesh gearbox is not compact as compared to a synchromesh gearbox.

These problems lead General Motors to develop synchromesh gearbox which is still used in almost 52% of the automobile vehicles on the road today.

Also Read:

- Types of Gearbox – Complete Explanation

- Different Types of Engine

- Types of Chassis and Different Types of Cars According to Body Style

Main Components

1. Shafts –

Just like constant mesh gearbox, there are 3 shafts used in synchromesh gearbox-

(i) Main shaft- Same as constant mesh a splined shaft is used as the output shaft over which the synchronizers and gears are mounted.

(ii) Lay shaft- It is the intermediate shaft over which gears with suitable size and

teethes are mounted and is used to transmit the rotational motion from clutch shaft to the final output shaft.

(iii) Clutch shaft- It is the shaft used as an input shaft in gearbox as it carries the engine output to the gearbox, same as the constant mesh gearbox

2. Gears-

There are normally 2 types of gears used in this –

(i) Helical gears- These gears are having angular cut teethes over a cylindrical metal flank.

(ii) Bevel gears – These gears are having angular cut teethes over a conical metal flank.

3. Synchronizers –

They are the special shifting devices used in the synchromesh gearbox which has conical grooves cut over its surface that provide frictional contact to the gears which is to be meshed in order to equalise the speed of main shaft, lay shaft and clutch shaft which in turn provides smooth shifting of gears.

4. Gear lever –

It is the shifting lever operated by the driver and is used to select the appropriate gear i.e. 1, 2, 3, 4, 5 or reverse gear.

Working of Synchromesh Gearbox

Selecting gears in synchromesh gearbox is somewhat same as constant mesh gearbox that are-

First gear

When the driver push or pull the gear lever in order to select the first gear which gives the maximum torque and minimum speed and is used to move the vehicle from its initial state ,the synchromesh device attached with the pair of meshed gears having biggest gear of the main shaft and smallest gear of the lay shaft equalises the speed of the shafts by making frictional contact with the pair and finally the first gear is obtained.

Second gear

This is the gear having lower torque and higher speed than first gear and is obtained when the pair of gears having second largest gear of the main shaft and second smallest gear of the lay shaft is meshed by the corresponding synchromesh device.

Third gear

This gear having higher speed and lower torque than second gear is obtained when the corresponding synchromesh device attached to the pair of gear having intermediate size gear of main shaft and intermediate size of gear of lay shaft makes contact.

Fourth gear

It is the second highest speed gear which is obtained when the corresponding synchromesh device attached to the pair of meshed gears having the second smallest gear of the main shaft and the second largest gear of the lay shaft makes contact.

Fifth gear

It is the highest speed and lowest torque gear which transmit the maximum speed of the clutch shaft to the main or output shaft and is obtained when the corresponding synchromesh device attached to the pair of meshed gear having smallest gear of main shaft and largest gear of the lay shaft makes contact.

Note – In some vehicle like ktm duke 390cc overdrive is attached which directly obtained the output from the clutch shaft and transmit to the final drive when the vehicle is on a long run with high speed or when the vehicle is going down the hill.

Reverse gear

It is the gear that reverses the direction of the output shaft which in turn reverse the direction of the vehicle with the help of the idler gear which is usually fit in the middle of the lay shaft and main shaft and is obtained when the idler gear makes contact with the gears on the main shaft and lay shaft.

Note – The reverse gear does not have any synchronizer mechanism, so the gearbox shaft rotation is completely stop before engaging the reverse gear.

For Complete Understanding Watch the Video Given Below:

Application

It has a wide application as almost 50% of the vehicle on the road used synchromesh gearbox, some of them are-

- In Maruti Suzuki swift it comes with 5-speed 1-reverse manual transmission configuration.

- It is used in bikes like ktm duke 390cc.

- Most of the race cars like formula-1 uses synchromesh gearbox with suitable modification in shifting lever as they required sudden shifting of gears from high torque to high speed because they have to race on the zig-zag track having sharp turns.

Conclusion

In this post, we have learnt about what is Synchromesh Gearbox, its main parts and how it works. I hope you have understood it clearly. If you found this piece of information valuable and useful then don’t forget to like and share it.