The era preceding the Industrial Revolution saw the manufacturing of products by a lone artisan, at times even by a team of artisans who carefully looked after each and every aspect of a part right from the beginning to the very end. Such a process could be a long and arduous one and would not be conducive for mass production. The difficulty level of even producing a single part was quite high. However, with the birth of the assembly line, the process of manufacturing saw a positive development. Smaller pieces of the part could be added in a particular order to the part as it moved from station to station and was finally ready and complete. The process was then known as progressive assembly and brought many improvements and benefits to those involved in the manufacturing industry.

Proces of Progressive Metal Stamping

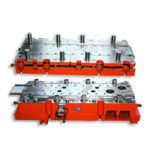

The process of progressive metal stamping involves creating metal parts or products by using various shaping methods and progressive tools and dies in a certain stepwise fashion. Progressive tools are utilized in an automated feeding system that moves the metal through various workstations. As the metal moves through all the arranged steps and gets stamped step by step through these progressive tools the end product is a part or component that is precisely designed for the purpose. After the progressive tool press sends out the finished part, it could need some final polishing or cleaning even trimming at times to get rid of the extra material. These steps are done separately or even on the same press having progressive tools.

Also Read:

- What is Slotter Machine?

- What is Lathe Machine? Main parts, Operations and Working

- What is CNC Machine – Main Parts, Working, Block Diagram

There are several shaping steps that are used to make stamped metal parts from sheet metal using progressive tools. These steps include coining in which a large amount of force is applied to change the shape of the sheet metal using progressive tools by displacement. Another operation called bending aims at achieving 90 degree angles to the part being produced using progressive tools. If holes are required, these are punched using a punch press and a counter supportive die and progressive tools. If a roll of gauged wire is used to create a shape or bend it is called Wireforming. The process of fine blanking using progressive tools helps create features that are not attained by means of the traditional cutting or punching action. For creating metal parts that have greater depth than its diameter, the process of deep drawing is used by means of progressive tools.

This versatile process of progressive stamping uses a variety of metals to create parts for different purposes. These metals include but are not limited to aluminium, brass, galvanized steel, copper, stainless steel, hot and cold rolled steel, zinc and even titanium.

Benefits

Some of the benefits of progressive stamping have been mentioned earlier, however, there are many more. With the help of progressive tools it is possible to produce parts or components in high volumes. No matter what the material being used is, the amount of wastage is kept to a minimum as the process itself generates very less or minimal scrap. As the entire set up of progressive tools stamping press is a one-time affair, multiple operations can be carried out in one go. This helps save a considerable amount of time in the production process. As progressive tools are used in the stamping process, it is possible to create different forms and shapes with just one operation. Since the entire process is carried out using progressive tools, it is easy to repeat the process as many times as required. The failure rate is very low and so is the rate of failed parts. The amount of downtime is also limited as the process needs fewer tooling changes. It is possible to carry out longer production runs using presses having progressive tools. With all the above mentioned benefits, the cost per part is kept low. The entire process is fast and the output generated is maximum with the help of progressive tools.

Today many different industries benefit from progressive tools and metal stamping processes. These include:-

- Electronics

- Aerospace

- Defence military

- Automotive

- Health care

- Home appliances

Manufacturers that use progressive tools to produce stamped parts offer the capability to cater to the needs of their clients no matter how complex the requirement of the stamped part is. Progressive tools are a part of press machines that are state of the art, producing intricate designs in metal parts with great efficiency.