Introduction

After reading the heading of the post. If you can guess the answer of the question than its good but don’t worry if you get failed. Because in this article I will give every possible information about gas turbine power plant, its definition, working principle and how it works. So, without wasting time let’s begin our discussion from its definition.

What is Gas Turbine Power Plant?

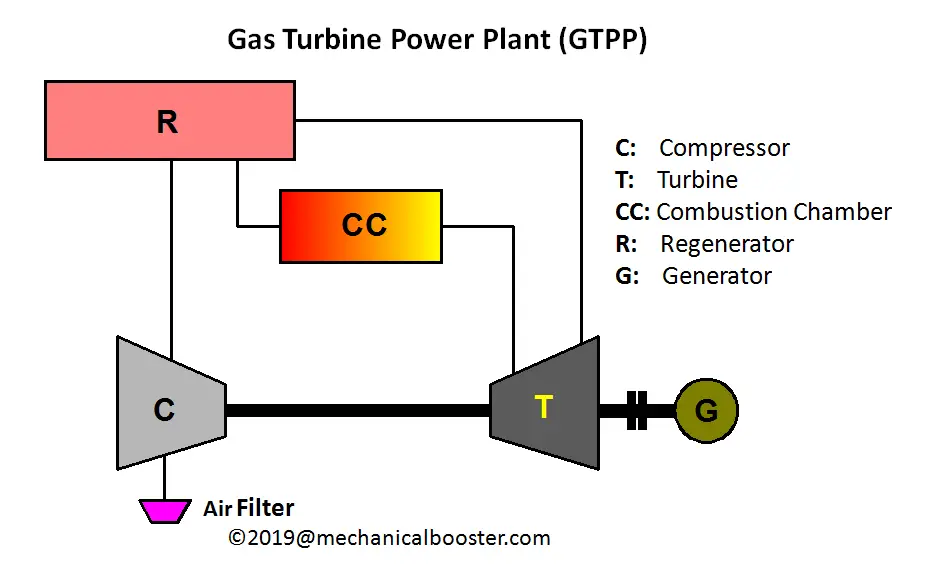

A Gas turbine power plant is a power plant which uses gas turbine to produce electricity. Now a question hit to our mind that how this electricity is produced by the gas turbine. So before understanding about the working of the GTPP. We must have a deep understanding of its main parts. So let’s first understand the main parts of it than we will move to its working.

Main Parts

- Compressor: It is a mechanical device that is used to compress the air to a high density. The compressed air helps in the burning of the fuel. The compressor and turbine have a common shaft.

- Combustion chamber: It is the chamber where the burning of the fuel in the presence of the air takes place.

- Gas Turbine: It consists of rotter blades. The hot gases produced due to burning of the fuel in the combustion chamber strikes on these blades and it starts rotating.

- Generator / Alternator: Electric generator is coupled with the shaft of the gas turbine. It rotates with the turbine shaft and produces electricity.

Also Read:

- What is Combined Cycle Power Plant? – Complete Explanation

- Nuclear Power Plant – Working Principle, Advantages, Disadvantages with Diagram

- Solar Power Plant – Main Components, Working, Advantages and Disadvantages

Construction Details

1. Compressor:

A rotary type air compressor is used in the gas turbine power plant. At the inlet of the compressor, filtration of the air has been carried out from the dust due to the air filter. The compressor plays the role of compressing the air and increasing the pressure of the air.

2. Regenerator:

The exhaust gases always carry the heat and that heat is used in the regenerator for increasing the temperature of the compressed air. In short, in the regenerator, the compressed air passing through the fine tube of the regenerator mixes with the exhaust gases resulting in the rise of temperature of the compressed air.

3. Combustion chamber:

The hot air from the regenerator then, enters into the compression chamber. The burners inside the combustion chamber do the role of injecting the fuel oil in the form of oil spray. The compressed air from the regenerator gets heated to 3000ºF due to the burning of the oil. This compressed-air then mixes with the combustion gases and cools down to the 1300º to 1500ºF.

4. Turbine:

In the turbine, mixing of the combustion gases and compressed air takes place. The kinetic energy is produced inside the turbine and also, the temperature of the gas again comes down to 900º F.

5. Alternator:

Inside the alternator, there is a rotor. The rotor of the alternator and the turbine has the same shaft. The alternator produces required electrical energy.

Working Principle of Gas Turbine Power Plant

First, all air is compressed inside the compressor. This compressed-air enters the compression chamber and gets heated. After that, this highly heated and pressurized air comes into the turbine. In the turbine, the expansion of the air takes place and it acquires kinetic energy and rotates the turbine blades. Now, this kinetic energy is converted into electrical energy with the help of a generator (alternator) coupled with the turbine shaft.

Fuels:

Now, let us talk about the choice of fuels in the gas turbine power plant. Natural gas is the most suitable fuel as it cheaper and also emits low Carbon Dioxide. Due to this, less pollution is produced. It is to be noted that fuel must not emit pollutants like carbon monoxide, nitrogen oxides after the combustion.

Difference between the Gas Turbine Power Plant and Steam Turbine Power Plant:

Gas turbine and steam turbine power plant both seem to be similar. But, in the GTPP, compressed air is used while, in that of the steam turbine power plant, compressed steam is used. The main goal of both of these power plants is the same that is to generate electricity.

Also Read:

- How Hydropower Plant Works? – Complete Explanation

- How Geothermal Power Plant Works – Explained?

- What are Different Types of Turbine?

Advantages

- GTPP has a simple structure. But the steam turbine power plant is structurally more complicated.

- Gas turbine power plant is dimensionally smaller than other types of power plants. So, it can be installed in a compact size area.

- The cost of maintaining this power plant in the working condition is very less.

- The GTPP gives rise to less amount of pollution and you require a less amount of water supply to operate it. As water requirement is less, such power plants are popularly used in the places where there is a scarcity of water and electric energy requirement is more.

- No need for condenser and boiler while operating the gas turbine power plant.

- It requires cost effective fuels. We can use cheaper fuels such as kerosene, benzene to run the power plant.

Disadvantages

- When power plants are considered then, their efficiency is the most important factor that we have to consider. The gas turbine power plant has low thermal efficiency. This lower efficiency of the GTPP leads to the limitations in its applications.

- From a compressor, due to high frequency, noise is generated. This leads to the noise pollution.

- Heat from the surface is carried out by the exhaust gases which also reduces the efficiency of this power plant.

- It is not suitable for production of electricity in our daily applications.

- For making of the gas turbine, a large cost is required. The operating temperature inside the GTPP is higher. Hence, special metals and alloys are used while constructing it.

Applications

- GTPP find its applications in the large compressor, high speed cars.

- They are also used for power generation in ships and aircrafts.

In this article, we covered all the detailed about the Gas turbine power plant. Let us know if you have any questions about it in the comment box.