So, are you looking for the most complete and perfect information about the Combined Cycle Power Plant (CCPP)? Then, you have just landed on the most appropriate article. Because in this article, we are going to learn about it in detail. So, are you excited to learn and grow? Let’s get started.

What is Combined Cycle Power Plant (CCPP)?

Combined Cycle Power Plant is used to generate electricity. Most of the time, it is also termed as the Combined Power Gas Turbine. It is also abbreviated as the CCPP. The primary purpose of using this power plant is to produce more electricity with higher efficiency. According to the reports, this plant produces 50% more electricity than that of the non-renewable sources of energy.

Working Principle:

Now, let us talk about the working principle of the Combined Cycle Gas Turbine. As it utilizes, both the gas and steam turbine for the production of the electricity, its working principle is same as that of the single-cycle power plant in the first half. So, in the first half, power is produced with the help of the gas turbine. Now, the waste of the first process, which means the waste in the form of heat is utilized in the second half, in the steam turbine to produce the additional electricity. The role of the Heat Recovery Steam Generator in the second half is crucial.

Main Parts:

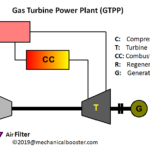

This combined cycle power plant has the main parts like compressor, combustor, turbine, alternator (generators), condenser, boiler feed pump and the Heat Recovery Steam Generator (HRSG).

The Diagram of CCPP is given below

Let’s discuss the role of each part in detail

1. Compressor:

It compresses the gases to high temperature so that oxygen in high density is available in the combustion chamber for efficient burning of the fuel. As we all know Oxygen helps in the burning of anything.

2. Combustor

It is an area in the gas turbine where the combustion of the entire fuel takes place. It is also called a combustion chamber. It receives the high-pressure gases from the compressor for the burning of the fuel.

3. Turbine

It is the most important part and has rotating blades. The burnt gases from the combustion chamber strikes the blades of the turbine and it starts rotating and produces electricity with the help of the generator coupled to its shaft.

4. Alternator or Generator

It is an electric generator coupled with the shaft of the turbine and converts the mechanical energy of the turbine into electricity (alternating current). The electricity produced here is A.C. and hence this type of electricity generator is called as an alternator.

5. Condenser

It is used to condense the hot exhaust steam to water.

6. Boiler Feed Pump

It a type of centrifugal pump used to deliver water to the boiler for the steam generation process.

7. Heat Recovery Steam Generator (HRSG)

It is used to recovers the heat from the hot gases of the gas turbine to produce steam for the steam turbine in the CCPP. As it generates steam by the heat recovers from the hot gases of gas turbine it is called HRSG.

Also Read:

- Steam Power Plant Construction,Working, Advantages and Disadvantages with Diagram

- Solar Power Plant – Main Components, Working, Advantages and Disadvantages

- Nuclear Power Plant – Working Principle, Advantages, Disadvantages with Diagram

Working of Combined Cycle Power Plant

Now, we would focus on the most important part of this article which is nothing but the working of the combined cycle power plant. See the below points to know the exact working of it:

1) Burning of the fuel inside the gas turbine:

Initially, the gas turbine compresses the air and fuel is mixed which in turn heated to extremely high temperature and burning of the fuel takes place. The burnt hot gases are then passed through the blades of the gas turbine, which starts rotating. The spinning of the blades of the gas turbine then drives a generator which converts the rotational energy into electrical energy.

2) Use of the exhaust heat:

The heat of the exhaust gas that comes out from the gas turbine is utilized by the heat recovery steam generator. Heat recovery steam generator uses the heat to convert water into steam which goes into the steam turbine.

3) Generation of the additional electricity by the steam turbine:

Steam turbine converts high-velocity steam energy into mechanical energy (rotation of the steam turbine Blades ). A generator is also coupled with the steam turbine that converts the mechanical energy of the turbine into electricity. Exhaust steam from the steam turbine is passed to the condenser where it is changed to the water. And then this water is again transferred to the boiler with the help of the feedwater pump for the generation of the heat again.

So, these are the three main vital steps in the working of the Combined Cycle Power Plant. We hope that you understand this working properly. If you have any queries about the working then, let us know in the comments section.

For Better Explanation Watch the Video Given Below:

Also Read:

- How Geothermal Power Plant Works – Explained?

- How Hydropower Plant Works? – Complete Explanation

- How Wind Power Plant Works?- Complete Explanation

Advantages:

Do you know the advantages of the CCPP? You may be guessing some of them. Following are the benefits of the CCPP:

- Low Capital:

If you consider the coal plant and the combined cycle plant then, for building a combined cycle unit you require half of the money than that required for constructing the coal power plant.

- The abundance of fuel sources:

For running the CCPP, you have large fuel resources like natural gas. Nowadays, biogas is also in use for operating the CCPP.

- Less emission:

As compared to the traditional power plant, the CCPP emits less, and it also burns the natural gas in a cleaner way. Thus, it is quite environment-friendly, and it affects the environment to a very small extent.

- Brilliant efficiency:

As previously stated, the combined cycle power plant is more efficient than the traditional power plant and energy production methods. It produces electricity with more than 50% efficiency than that of the conventional resources.

- Large availability:

The combined cycle units are available anywhere in the world. They are very flexible if their transportation is considered.

Disadvantages:

If you talk about the disadvantages then, there are some disadvantages of the combined cycle power plant. Following are some of them:

- Building this power plant is quite complex. That means that it has to be designed and test properly. A single mistake can ruin the entire area around those power plants.

- High Maintenance cost: Maintaining such complex systems is another challenging part. Care should be taken of every part regularly.

- It uses natural gas and biogas. Therefore, it can be constructed in places where these gases are present. So, it is an area bound power plant.

Efficiency of Combined Cycle Power Plant

The Efficiency of CCPP is more than 50% which is much better than the other non-renewable sources of power plants. It is the best power plant to produce electricity with greater efficiency.

Applications:

The CCPP is used in more than 4000 applications such as in industry, hospitals, various institutions, etc. It has been mainly used in hospitals and the manufacturing of ethanol, glass, pulp, and paper. Many refineries, sawmills as well as plastic industries are using the CCPP.

Conclusion:

As there is always the need for energy, the combined cycle power plant is the best choice we have. Many researchers are working on the CCPP to increase its efficiency as well as to reduce its effects on the environment. In this article, we learned all about the CCPP. If you find this article helpful then, please take a moment to share it!