Today we will learn about what is carburetor – parts and its working. As we know spark ignition engines use volatile liquid fuels such as petrol for its working. Petrol is highly volatile and its ignition temperature is quite below the temperature that occurs in the engine cylinder before full compression. Hence, the mixing of air and fuel isn’t possible inside the engine cylinder of SI engines. But we require a properly mixed, homogenous mixture of air-fuel in the correct ratio for proper combustion. This needs a device that can mix air-fuel in the correct ratio and form a homogenous mixture outside the cylinder. This device is known as Carburetor.

What is a Carburetor?

A carburetor is a device that is used in a spark ignition engine to mix air-fuel in the correct ratio outside the cylinder. This process is known as carburation.

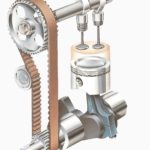

Carburetor Parts

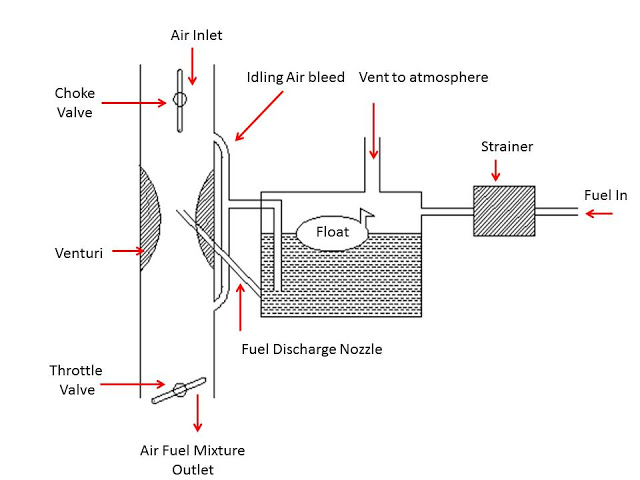

1. Float Chamber:

The float chamber serves as a storage tank of fuel for a continuous supply of fuel. It contains a float valve that maintains the level of fuel in the float chamber. When the level of fuel decreases in the float chamber the float moves downward, which opens the fuel supply valve and allows the flow of fuel into the float chamber. As the fuel level increases, the float moves upward which closes and stops the fuel supply. This fuel level is maintained below the discharge nozzle outlet hole to prevent overflow.

2. Strainer:

It is a device that is used to filter the fuel before entering the float chamber. It consists of a fine wire mesh which filters the fuel and removes dust and other suspended particles from it. These particles if not removed can cause blockage of nozzle.

Also Read:

- Difference Between SI Engine and CI Engine

- Different Types of Engine

- What are the Main Parts of an Automobile Engine?

3. Metering System:

The metering system controls the flow of fuel into a nozzle. It is responsible to form the correct mixture of air fuel. It consists of two main parts, the first one is known as a metering orifice, and the other one is known as a fuel discharge nozzle. When the air passes through the venturi, it generates a low-pressure field across the throat compared to pressure at the float chamber. Due to this pressure difference, fuel is discharged into the air stream. The quantity of fuel is controlled by the metering orifice and discharge hole at the exit of the fuel discharge nozzle.

4. Idling System:

It consists of a passage directly from the float chamber to the venturi tube. It provides a rich mixture during idling and at low speed. It works during idling or when the throttle is open below 15%.

5. Throttle Valve:

It is a butterfly valve situated at the exit of the venturi tube. It controls the speed of the vehicle by providing a controlled amount of mixture. It controls the quantity of air-fuel mixture. If the throttle is fully opened, then more mixture is drawn into the cylinder and thus gives high output. But if it is little opened, less mixture is drawn into the cylinder, which gives less power.

6. Choke Valve:

It is the same as the throttle valve in construction but situated at the entrance of the venturi tube. It is used to provide a very rich mixture during starting in the cold season. It controls the quantity of airflow through the venturi tube. If the choke is fully open, a normal amount of air flows through the venturi, which forms a normal mixture. But if the choke is partially closed, it results in a low amount of air flow through venturi and a large amount of fuel flow through the discharge nozzle. It gives a rich mixture.

Also Read:

- Manual-vs-Automatic-Transmission

- What is Fuel Injector and How it Works?

- Types of Gearbox – Complete Explanation

Working of Carburetor:

Now we know about the basic parts of the carburetor and its function. These all parts work together to perform the common function of providing a homogenous air-fuel mixture in the proper ratio. Its working can be summarized into the following points.

- First fuel is supplied into the float chamber through a strainer. The strainer works as a filter. It does not allow dust and other suspended particles into the float chamber which can choke any fuel passage.

- The float maintains a constant level of fuel in the float chamber. If the amount of fuel in the float chamber goes down below the designed limit, the float goes down which opens the fuel supply valve and allows fuel to flow into the float chamber. If the fuel reaches the designed limit, the float goes up, which closes the fuel supply valve and thus stops fuel supply into the float chamber.

- The fuel discharge nozzle connects the float chamber to the venturi tube. One end of the fuel supply nozzle is connected to the bottom of the float chamber and the other one is to the venturi tube slightly above the designed fuel level in the float chamber. This will avoid overflow when the engine is not running.

- During suction stroke air is drawn into the cylinder through the venturi tube. Venturi is a tube of decreasing cross-section and has a minimum area at the throat. The fuel supply nozzle connects at the throat of the venturi tube. This air has a maximum velocity at the throat. Due to this high velocity, the pressure at the throat goes down below float chamber pressure.

- This will create a pressure difference between the float chamber and the venturi tube. This pressure difference is known as carburetor depression. It acts as a driving force for fuel. It drives fuel from the float chamber to the venturi tube through a fuel supply tube and the fuel is discharged into the air stream.

- The fuel-air ratio depends on the size of the discharge jet and metering system. So they are chosen as such, they can give the desired air-fuel ratio.

- This air-fuel mixture is provided to the cylinder through the throttle valve. The SI engine is a quantity-governed engine. So the quantity of the mixture provided into the cylinder is controlled by the throttle valve and hence controls output power.

- For idling or when required rich mixture, extra fuel is supplied by the idling system into the venturi tube.

Conclusion

This is all about what is carburetor – main parts and working. If you have any queries regarding this article, you can ask us through your valuable comments. If you find this piece of information valuable and useful then don’t forget to like and share it.

Author Bio:

Mitesh Bairwa is a Mechanical Engineer by profession and a blogger by hobby. He is the owner of www.mech4study.com.