Introduction

A mechanical drive system is a mechanism, which is intended to transmit power and motion over a certain distance typically involving vary in speed and torque. Both Belt and chain drive are the part of mechanical drive system and are used for transmission of power from prime mover or Driving shaft to Driven shaft. These systems are widely used in various applications in order to convert rotational motion into translational motion. They utilize various mechanical elements which are in physical contact with each other for power transmission.

There are 4 mechanical drives mainly: Belt drive, Chain drive, Gear drive, Rope drive. Each of them has respective pros and cons; thus suitable for specific applications. These 4 drives can be classified on the basis of power transmission. When a power is transmitted by means of friction force then these are called friction drive such as belt and rope drive. When power is transmitted by means of engagement then it is known as engagement drive such as chain and gear drive.

There are many other drives apart from mechanical, such as Hydraulic, Pneumatic, Electrical drive which have different applications in various fields. The selection of mechanical drive depends upon various parameters such as velocity ratio, distance between shafts center, shifting arrangement and finally cost and, maintenance considerations. Here we will study the difference between chain drive and belt drive or chain drive vs belt drive in detail.

What is Belt Drive?

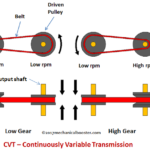

Belt drives are the cheapest mode of power transmission between shafts that may not be axially aligned. It is a mechanism in which power is transmitted through a continuous movement of flexible belt over the pulley mounted on each shaft. It is also known as friction drive because the friction plays an important or primary role in it. This force acts in the opposite direction of belt movement and decides the amount of power transmission. Both frictional force and power transmission are directly proportional to each other.

These belts are generally made of rubber, fabric rubber, ply leather, or synthetic material which prone to change in dimension because of external or, atmospheric conditions. The degree of change depends upon the thermal expansion of material thus when the temperature goes high, the length of belt increases which leads to an increase in slippage of the belt over the pulley and loss of power and which results in unstable velocity, and degraded efficiency.

What is Chain Drive?

It is a mechanism in which power is transmitted by means of continuous flexible engagement and disengagement of chain and sprocket from one shaft to another. It is also known as positive drive which has a fixed velocity ratio. It is often seen or used in motorcycles and bicycles to convey power to a wheel from a shaft (prime mover). However chain drive is used where distance between the shafts is less. However, this is not always true. In some cases, if the distance between the shafts is large, then idler sprocket or gear is used in intermediate position to provide the required tension in the chain.

A chain is made by number of links, made of metal, and is connected with the help of a pin. These chain runs over a sprocket which has number of teeth around its circumference.

Also Read:

- Manual Vs Automatic Transmission

- Drum Brakes vs Disc Brakes – Which is Better?

- Difference Between NC and CNC Machine

Difference Between Chain Drive vs Belt Drive

Now let’s understand the difference between the Belt drive and Chain drive.

| Particulars | Belt Drive | Chain Drive |

| Type of mechanical drive | It’s come under the category of friction type mechanical drive where friction force between belt and pulley is used to transmit motion and power. | It’s come under the category of engagement type of mechanical drive where power is transmitted through continuous engagement and disengagement of chain with sprocket teeth. |

| Slip | It’s a non – positive drive where slippage occurs between belt and pulley if load capacity exceeds the rated capacity. | It’s a positive drive which is free from slippage. |

| Velocity Ratio | It changes due to various parameters. | Remains constant |

| Recommended for low velocity ratio | Recommended for moderate velocity ratio | |

| Suitability | From medium to larger center distance between driver and driven shaft. | From shorter to medium distance between driver and driven shaft. |

| External factors effect | Affected by atmospheric aura or temperature thus performance changes. | No affect |

| Alignment | Suitable for parallel alignment between driver and driven shaft, though some error doesn’t effect on machine or its working condition. | Strictly advice for complete alignment of parallel shafts. |

| Installation cost | Required less | More as compare to belt drive |

| Maintenance cost

|

Minimum or less | Regular maintenance needed. |

| Durability | Less strong and durable because material is made of rubber, fabric rubber, ply leather, or synthetic material. | More durable and stronger because material made of metal |

| Face | Only one face of the belt drive can be used. | Both side faces can be used. |

| Efficiency | It is comparatively low, around 92-96%, because of frictional loss | It is higher, around 95-98%, because of barely any friction loss. |

| Life | Less because of frictional loss | Comparatively more. |

| Lubrication | Not required or very often. | Regular lubrication needed |

| Example | Treadmills, mill industry, sewing machines, etc. | Used widely in bikes, automobiles industry, mining industry, military industry, etc. |

In this article, we learned about the difference between chain drive and belt drive in detail. If you found this piece of information valuable then don’t forget to like and share it.