Introduction

Fond of automatic transmission? Of course, you are, who would resist the comfort of driving an automatic vehicle, but have you ever wondered how it works? Yes, you do now; In this era of modern automobile vehicles, automatic transmission is one of the hot area for car manufacturers because of that we have various types of automatic transmission available today. One from them is a “Continuously variable transmission” (see our article on C V T)

Let’s start with an interesting fact about continuously variable transmission, the idea of continuously variable transmission is given by one of the greatest minds of the time i.e. “Leonardo – da – Vinci” in 1490.

In this article, we will learn about how cvt works in detail. So lets began with its definition.

What is Continuously Variable Transmission (CVT)?

A continuously variable transmission system is a type of automatic transmission in which an arrangement of pulleys and belts made it possible for a drive to achieve n-number of continuous gear ratios within a range (depends on the design).

A continuously variable transmission in a vehicle senses the accelerator input with engine load and get shifted to the desired speed or torque gear ratio automatically, in other words we can say that a cvt transmission is one of the simplest types of automatic transmission that provides continuous uninterrupted power within a specified range of speed and torque ratios.

To understand how it actually work first lets understand cvt’s construction.

Construction Details

When it comes to the construction of a continuously variable transmission as we have already discussed its design is very simple so let’s just understand the various components that comes together to make cvt-

1. Pulleys –

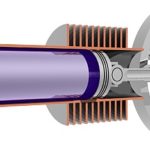

In Cvt pulleys play an important role as the conical shape pulleys integrated over input and output shafts are the reason for continuously variable transmission’s continuous n-number of speed and gear ratios, due to the different cross section of these conical pulleys multiple torque and speed ratios are obtained.

Two pair of conical pulleys each for input and output shafts are used in a basic continuously variable transmission that are-

- Fixed input pulley-It is a conical pulley mounted over the input shaft (on the right-hand side), this pulley does not move (too and fro) over the shaft but rotates with the input shaft, usually fixed pulley is smaller in size.

- Fixed output pulley-same as fixed input pulley but unlike fixed input shaft this shaft is placed on the left-hand side over the output shaft.

- Feeding input pulley or sheave- It is the type of conical pulley which is mounted over the input shaft and have inner splines meshed with the shaft splines in such a fashion that it can move (too and fro) as well as rotates with the input shaft. The too and fro moment of this shaft over the input shaft make it possible to shift gear ratios.

- Feeding output pulley or sheave- Same as moving input pulley but unlike moving input shaft, this shaft is placed on the right-hand side over the output shaft.

Also Read:

- How Automatic Transmission Works? – Best Explanation Ever

- Manual Vs Automatic Transmission

- What is Manual Transmission and How it Works?

2. Shafts –

Same as manual transmission type 2 shafts are needed by Cvt transmission to transfer power from engine to the final drive that are-

- Input shaft- Same as the manual transmission it is a type of shaft having splines over its cross-section over which input pulleys are mounted, the power source for this input shaft is engine which means continuously variable transmission gets the input from the engine through input shaft.

- Output shaft- It is the type of shaft which is kept parallel to the input shaft in a continuously variable transmission, same as input shaft it also has splines over its cross-section and is mounted upon by output pulleys.

Output shaft is responsible to transmit final output power to the final drive of the vehicle.

3. Belt or Chain-

In a Cvt transmission a v-shaped metallic (rubber in some case) chain or belt is used to transmit power from input pulleys to the output pulleys as

this belt or chain is wrapped over both conical input and output pulleys pairs and the V-shape of this belt or chain make it possible to shift gears from high torque to the high speed.

How CVT Works?

As we all know the basic function of any transmission system whether manual or automatic is to provide variable speed or torque ratios as per the requirement of the drive.

After reading the construction of the continuously variable transmission, I assume that the basic picture or design of a cvt is clear in our mind, right? So, let’s just convert that picture into a video and first let’s understand the basic power transmission of a Cvt transmission –

- When a driver presses the accelerator pedal or accelerator handle (in case of 2-wheelers) the engine shaft rotates according to the accelerator input which in turn rotates the input shaft.

- With the input shaft rotation, input pulleys mounted over it also rotates which in turn rotates the belt wrapped around them.

- This belt transfers power from input shaft to the output pulley as it is also wrapped around the output pulleys.

- output pulleys rotate the output shaft and final output is obtained.

Note-

The right to left or vice -versa movement of pulleys (depending upon the acceleration input and need of the vehicle) over input and output shafts make it possible to attain desired torque or speed ratio.

Now this was how the power transmission from engine shaft to the continuously variable transmission’s output shaft takes place now let’s understand how we get different speed and torque ratios-

Also Read

- Torque Converter Working, Principle, Main Parts and Application.

- What is an Overdrive and How it Works?

- What is Master Cylinder and How It Works?

Torque ratios

when a vehicle needs high torque ratios the feeding input conical pulley (sheave) over the input shaft moves away from the fixed pulley which in turn shift part of the v-belt wrapped over the input pulleys towards the lower cross-sectional part of the conical pulley.

Simultaneously when this input pulley(sheave) moves, feeding output pulley(sheave) also moves and comes closer to the fixed output pulley which in turn shift the part of v-shaped belt wrapped over the output pulleys towards the greater cross-sectional area of the output conical pulleys and desired torque ratios is attained.

Speed Ratios-

when the vehicle needs speed ratios, the feeding conical pulley (sheave) over the input shaft moves towards the fixed pulley which in turn shifts the part of v-shaped belt wrapped over the input pulleys towards the greater cross-sectional part of the conical input pulleys.

Simultaneously with this movement of input pulley, feeding output pulley (sheave) also moves and go away from the fixed pulley which in turn moves the part of the v-shaped belt wrapped around the output pulleys towards the lower cross-sectional part of the conical output pulleys and desired speed ratio is attained.

In other words, torque ratios are achieved when the v-belt rotates at the lower cross section of the input pulleys and at the greater cross section of the output pulley.

And speed ratios are achieved when v-belt rotates at the higher cross section of the input pulley and lower cross-section of the output pulley.

For Better Understanding See the Video-

Application

The Cvt works in the following vehicle given below:

- Honda Activa, Suzuki Access.

- Nissan micra.

- Audi A4

- Jeep compass.

Conclusion

In this article, we have learnt about What is CVT and how it works. I hope you have understood it clearly. If you find this article useful than don’t forget to like and share it.

![What are the Components of an Automobile? [Complete Guide] Main components of Automobile](https://mechanicalbooster.com/wp-content/uploads/2013/04/Main-components-of-Automobile-150x150.jpg)