What is Open Die Forging?

Open die forging is a type of forging in which the metal pieces or workpiece are deformed to the desired shape with the help of dies that do not completely enclose the material. The material produced in the open die forging requires secondary machining operations to get the desired accuracy and tolerances. In this forging process the material is shaped by placing the workpiece on a stationary anvil and then hammering it with the help of a power hammer. Here the die is attached to the hammer or the hammer acts as die.

This forging technique is generally used to shape metal parts, steels, or alloy steels. The parts produced is not of greater accuracy and hence require machining operation on the lathes or milling machines, etc to give it the desired accuracy.

Main parts

The main parts of open die forging are

- Hammer/Ram: The hammer or ram is used to apply force on the workpiece.

- Die: A die is attached to the hammer or ram that makes contact with the workpiece to give it a desired shape and size. The die used in open die forging may be of flat, concave, and convex surfaces or a tool to make holes or to cut off part. The most common flat surfaces die is used.

- Anvil: It is a stationary part that supports the workpiece during the hammering.

- Workpiece: It is the metal parts that will be used to deform and changes it to the final product. The metal workpieces are heated to red hot before hammering.

Working Principle

In open die forging, the workpiece is heated and placed on the anvil and then it is hammered with the ram or hammer. The force of the hammer that makes contact with the workpiece compresses it and allows it to expand in the direction that is not in contact with the hammer surface and anvil. The hammering process continues and a skilled worker changes the orientation of the workpiece to give it the required shape.

When the workpiece gets cold during hammering, it is heated again and then the process continues until the final dimension is not obtained.

In this forging since the metal part is hammered continuously, the grains in the workpiece arranged themselves more uniformly and we get a finer grain size with the continuous flow that results in the greater strength of the final product.

The parts produced in the open die forging has greater strength, fatigue resistance, wear resistance, fine microstructure, fewer voids as compared with similar machined or cast parts

Also Read:

- What is Forging ? – Complete Explanation

- What are the Melting Points of Metals?

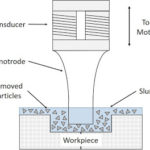

- What is Electrical Discharge Machining (EDM) Process and How it Works?

Working of Open Die Forging

let us understand the working of open die forging step by step

- Firstly the workpiece is heated to red hot temperature i.e. the temperature at which it can be deformed permanently.

- The hot workpieces are then put on a stationary anvil and compressive force is applied on it with the die that is attached with a power hammer.

- The compressive force of the die allows the workpiece to expand in the lateral direction i.e. it expands in all directions except the surfaces that are in contact with the die and anvil.

- High skilled labor changes the orientation of the workpiece to give it a desired shape and accuracy.

- The workpiece may be heated number of times if it gets cold and again the process of hammering continues until it does not take the desired shape.

Application

- It is used to produce simple parts such as discs, shafts (it includes step shaft or shaft with flanges), hubs, blocks, cylinders, sleeves, flats, rounds, hexes, and some custom shapes.

- It is also used to produce heavy parts that weigh in tons.

Advantages

The various advantages of open die forging are

- We get the product of greater strength.

- The fatigue resistance of the part gets improved.

- We get products with improved microstructure, fine grain size, and continuous grain flow.

- Less wastage of the material.

- The parts produced by this forging technique has reduced voids.

- It is capable of producing very large parts that may weight about 136 metric tonnes.

Disadvantages

- The parts produced in this forging process do not have high accuracy and close tolerances.

- Machining operation is often required to get the desired accuracy and features.