In DTSI engine, Dtsi stands for Digital Twin Spark Ignition. Before understanding DTSi technology, let’s understand why this technology is developed. Especially in internal combustion, which stroke is the main and effective stroke of an engine? Obviously, everyone is wondering about all the four strokes and started jumbling to find the better answer. Let’s come to one point if the burning of the air-fuel mixer would happen well then more power would be produced in the combustion chamber. So, in which stroke combustion of fuel takes place? It is at the end of the compression stroke which means it is a power stroke or expansion stroke which is started via spark plug and it is effective among the other three strokes available. By improving the power stroke may change the entire scenario of an engine’s performance.

Bajaj Auto Ltd has done some R&D on the power stroke and invented a new technology named DTSI ( Digital Twin Spark Ignition). In this technology, it uses two spark plugs for the combustion of fuel within the engine cylinder. The use of two spark plug increases the burning efficiency of the fuel and produces more power with less amount of fuel.

Working Principle

It works on the principle of twin spark produced by the two spark plugs. As compared with the single spark fired engines, in twin spark engines the combustion of the air-fuel mixture takes place at optimal level and it produces more power. Because of the use of twin spark plug, the spark produced is more which burns the fuel more efficiently and rapidly. It results in increase of mileage, power and less emission of exhaust gases. The Dtsi engine produces 26% more power as compared with conventional single spark engines of same capacity.

They are Digitally controlled by Electronic Control Unit (ECU)

Also Read:

- How Battery Ignition System Works?

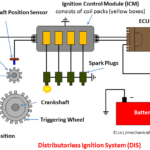

- What is Distributorless Ignition System (DIS) – Diagram, Working with Application

- Magneto Ignition System – Parts, Working Principle, Advantages and Disadvantages with Application

Main Parts of DTSi Egnine

1. ECU:

It is a heart of the DTS-I. ECU consists microprocessor chip with preprogrammed data of Ignition Timings for various engine rpm and engine loads. It controls the firing of spark plugs as per the requirement.

2. Spark plug:

It is a small device placed upon the cylinder head.In dtsi engine two spark plugs are used for the combustion of fuel. It is an initiator of the power stroke. The electrical energy (High Voltage) transmitted through it and creates a spark in the combustion chamber. Spark plug usually requires a voltage of 12,000-25,000 volt to produce spark.

Working of DTSi Engine

First of all, it is a technology in which two spark plugs are used. DTS-I stands for Digital Twin spark ignition. Basically, it has two spark plugs at the opposite end of engine cylinder head in 90 degrees; instead of one spark plug which is common in a conventional engine. Two spark plugs produces the spark during the power stroke according to input requirement.

According to engine load, RPM and at low-high speed the ECU sends the low and high- frequency pulses to spark plug to perform as per situations. Spark timing of these two spark plugs is controlled digitally. DTS-I engines are known for efficient burning of air-fuel mixer at right time.

Internal Process:

The conventional engine equipped with only one spark plug. After suction of air-fuel mixer piston can move BDC to TDC, it is called compression. At the end of compression stroke piston will be at TDC and before starting of power stroke compressed air-fuel mixer get spark via spark plug and burnt. Burnt fuel produces the energy which pushes the piston down side. With single spark plug produced flame diameter is less which take more time to reach other portion, it means the rate of combustion is slow (from top to bottom in the combustion chamber). But, dual spark plug can overcome this issue and create larger diameter flame which can burn the complete air-fuel mixer uniformly and quickly in very less time. Due to this reason force upon the piston would be great which leads to better work output.

Also Read:

Advantages

- Detonation can be reduced: DTSI engine cannot frequently undergo detonation because complete combustion of air-fuel will not create any disturbance between piston and wall.

- Better fuel efficiency

- Less emission of exhaust gases.

- Less vibrations and noise due to smooth function.

- Engine breathing performance is easy even at high rpm.

- No overheating issue.

- Complete combustion, No unburnt issue.

- Fast engine response even in winter and cold condition (Two spark plug).

Disadvantages

- Expensive

- Replacement of both spark plug even one is damage (Reason is series in connection, But parallel connection could not be achieved high voltage).

- Complex in design.

Applications

The application of this technology is widely used in BAJAJ engines Example; Discover 150, pulsar 150, 200, 220.