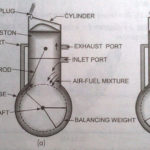

In this article, I going to describe to you how does a four stroke diesel engine work. Diesel engine which is also known as compression ignition engine is widely used in automobile industries. Many big vehicles such as trucks, buses, cars, etc. use the diesel engines as the power unit because of its higher torque and greater mileage than a petrol engine. The diesel engine is very popular in the Indian market as well as in other countries because of the lower price of diesel than petrol. So the requirement of diesel engine is much more than the petrol engine. The ignition temperature of diesel is lower than petrol so the working of diesel engine is slightly different than the petrol engine.

Working of Four Stroke Diesel Engine

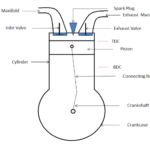

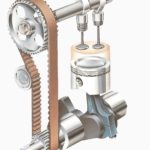

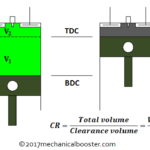

The power generation process in four stroke diesel engine is also divided into four parts. Each part is known as piston stroke. In IC engine, stroke is referred to the maximum distance travel by the piston in a single direction. The piston is free to move only in an upward and downward direction. In four stroke engine the piston move two time up and two times down and the crankshaft moves two complete revolutions to complete four-piston cycle. These are suction stroke, compression stroke, expansion stroke, and exhaust stroke.

Suction Stroke:

In the suction stroke or intake stroke of a diesel engine, the piston starts moving from the top end of the cylinder to the bottom end of the cylinder and simultaneously inlet valve opens. At this time air at atmospheric pressure is drawn inside the cylinder through the inlet valve by a pump. The inlet valve remains open until the piston reaches the lower end of the cylinder. After it, the inlet valve close and seal the upper end of the cylinder.

Also Read:

- What are Different Types of Engine

- How Electronic Ignition System Works?

- What is Difference Between Petrol and Diesel Engine?

Compression Stroke:

After the piston passes the bottom end of the cylinder, it starts moving up. Both valves are closed and the cylinder is sealed at that time. The piston moves upward. This movement of the piston compresses the air into a small space between the top of the piston and the cylinder head. The air is compressed into 1/22 or less of its original volume. Due to this compression, high pressure and temperature are generated inside the cylinder. Both the inlet and exhaust valves do not open during any part of this stroke. At the end of the compression stroke, the piston is at the top end of the cylinder.

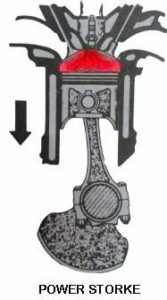

Power stroke:

At the end of the compression stroke when the piston is at the top end of the cylinder a metered quantity of diesel is injected into the cylinder by the fuel injector. The heat of compressed air ignites the diesel fuel and generates high pressure which pushes down the piston. The connecting rod carries this force to the crankshaft which turns to move the vehicle. At the end of the power stroke, the piston reaches the bottom end of the cylinder.

Exhaust Stroke:

When the piston reaches the bottom end of the cylinder after the power stroke, the exhaust valve opens. At this time the burnt gases are inside the cylinder so the cylinder pressure is slightly high from atmospheric pressure. This pressure difference allows burnt gases to escape out through the exhaust port and the piston to move through the top end of the cylinder. At the end of the exhaust, all burnt gases escape and the exhaust valve closed. Now again intake valve opens and this process runs until your vehicle starts.

For a Better Understanding of the working of four stroke Diesel Engine watch the video :