Introduction

From wind mills to hydro-power plants we have reaction turbines all around the world to generate electricity efficiently. Almost 60% of turbines used in hydro-power plants are reaction turbine. Unlike impulse turbines they remain dipped in water and use the pressure energy of water to generate power.

The idea of dipping the whole turbine into water came from Germany in mid twelfth century. The basic thinking was that we can use the weight of water to turn the turbine blades more efficiently compared to the water just striking the water wheel’s base. But it took a look time to built an efficiently working reaction turbine, which was built in mid 18th century by Benoit Fourneyron, who is said to be the inventor of modern hydraulic turbines, since then we are putting in our efforts to further improve our designs, to make them more and more efficient. So let’s just figure it out what we have in our modern reaction turbines.

Working Principle

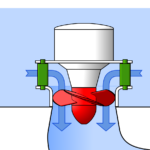

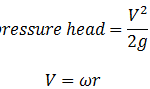

The working of the reaction turbine can be well understand by taking a rotor having moving nozzles and water of high pressure is coming out of the nozzle. As the water leaves the nozzle, a reaction force is experienced by the nozzle. This reaction force rotates the rotor at very high speed.

In the same way in reaction turbine, a reaction force is generated by the fluid moving on the runner blades. The reaction force produced on the runner blades makes the runner to rotate. Fluid after moving over the runner blades enters into draft tube and finally to the trail race.

Main Components

1. Spiral casing

It is a spiral casing, with uniformly decreasing cross- section area, along the circumference. Its decreasing cross-section area makes sure that we have a uniform velocity of the water striking the runner blades, as we have openings for water flow in-to the runner blades from the very starting of the casing, so pressure would decrease as it travels along the casing. So we reduce its cross-section area along its circumference to make pressure uniform, thus uniform momentum or velocity striking the runner blades.

2. Guide vanes

Guide vanes are installed in the spiral casing, their most important function is to make sure that water striking the runner blades must have a direction along length of the axis of turbine otherwise the flow would be highly swirling as it moves through spiral casing, making it in-efficient to rotate runner blades. The angle of these guide vanes is adjustable in modern turbines, and we can adjust the water flow rate by varying the angle of these guide vanes according to the load on the turbine.

3. Runner blades

Runner blades are said to be heart of a reaction turbine. It is the shape of the runner blades which uses the pressure energy of water to run turbine. Their design plays a major role in deciding the efficiency of a turbine. In modern turbines these blades can pitch about their axis, thus can vary the pressure force acting on them according to the load and available pressure.

4. Draft tube

Draft tube connects the runner exit to the tail race. Its cross-section area increases along its length, as the water coming out of runner blades is at considerably low pressure, so its expanding cross-section area help it to recover the pressure as it flows towards tail race.

Also Read:

Difference Between Impulse and Reaction Turbine

Types of Wind Turbines – Horizontal Axis and Vertical Axis Wind Turbines

Working of Reaction Turbine

Low head and high velocity water enters the spiral casing. And as it enters the casing it starts flowing through guide vanes into the runner blades. Guide vanes guides the flow of water to strike the runner blades at proper angle, to produce maximum power output. The water flowing through spiral casing is able to keep its pressure energy consistent throughout the circumference of spiral casing due to its uniformly decreasing cross-section area. These guide vanes can change their angle to increase or decrease the flow rate of water into turbine. And the runner blades are also made adjustable, as when the flow of water is fast and energy demand is less then they would pitch themselves to incline at a smaller angle with the axis of turbine. And when the load on the turbine is more and flow of water is less, they would adjust themselves at a greater angle with the axis of turbine. Two factors which determines the efficiency of a reaction turbine are the angle of attack of water when it strike runner blades, and the profile of runner blade over which water glides. Due to the adjustability of both the guide vanes and runner blades, we are now able to use this turbine over a wide range of water potential and load demands.

Water coming out after striking the runner blades, is at a really low pressure, so it is passed through a draft tube with uniformly increasing cross-section area to recover its pressure as it reaches the tail race. But unfortunately the pressure difference is too high to be recovered by a draft tube, so this results in the problem of cavitation and corrosion.

For better understanding about working of reaction turbine watch the video given below:

What is cavitation?

Difference in the pressure of water entering the turbine and that exists after striking the runner blades is too high, due to this pressure difference the air molecules which are relatively at high pressure then water coming out, enters the turbine casing in the form of bubbles. These bubble keeps on exploding near the surface of the runner blades continuously causing a shock wave, which produces a kind of defect at runners surface called cavitation, thus causing a serious problem for turbines efficiency. So what can we do is to prevent blades from cavitation? One solution is to use a really hard surface material like stainless steel or we can also go with surface Hardening of the runner blades, to prevent them from cavitation.

Applications

- Reaction turbine is used in wind power mills to generate electricity

- It is most widely used turbine in hydro-power plants, to generate electricity.

- It is the only turbine to get maximum power output from a low available water head and high velocity other than cross-flow turbine which not that efficient.

Great article! i loved the easiest diagram to demonstrate the working principle of the reaction turbine. Please write an article about the impulse and reaction turbine compounding ! Will be eagerly waiting for that ! Thanks Pankaj !

short but concise! great article!