The diesel cycle was invented by Rudolph Diesel in 1893. He put forward an idea by which we can attain higher thermal efficiency, with a high compression ratio. All diesel engine works on this cycle. Diesel is used as fuel in this cycle as it can be compressed at a higher compression ratio. It is also known as a constant pressure cycle because heat is added to it at constant pressure. It has a high thermal efficiency and compression ratio (11:1 to 22:1) as compared with the Otto cycle.

The engine that is put forward by Rudolph consists of an enclosed air in the cylinder. The cylinder walls are perfectly non-conductors of heat, but the bottom is a perfect conductor of heat. It has a hot body, a cold body, and an insulating cap, which are alternately brought in contact with the cylinder.

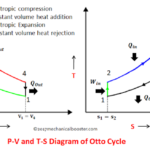

The ideal Diesel cycle consists of 4 processes, two isentropic processes, one constant pressure, and one constant volume process.

Processes

The 4 processes are as follows

- Isentropic (reversible adiabatic) Compression

- Constant pressure heat addition

- Isentropic Expansion

- Constant volume heat rejection.

Also Read:

- Difference Between Otto Cycle and Diesel Cycle

- How Power Steering System Works? – Best Explanation

- What is Magneto Ignition System and How It Works?

The working of these four processes of the Diesel cycle can be easily grasped with the help of the P-V and T-S diagrams.

Note: For a better understanding of the process, watch the P-V and T-S diagram wherever necessary.

Process 1-2: Isentropic Compression

In this process, the piston moves from BDC to TDC and compression of air takes place isentropically. It means that during compression the entropy remains constant and there is no flow of heat out of the cylinder walls (non-conductors) happens. Here the air is compressed so the pressure increases from P1 to P2, volume decreases from V1 to V2, Temperature increases from T1 to T2 and entropy remains constant ( i.e. S1 = S2).

Process 2-3: Constant Volume Heat Addition

In this process, the hot body is kept in contact with the cylinder and heat addition to the air takes place at constant pressure. During this process, the piston rest for a moment at TDC. The pressure remains constant (i.e. P2 = P3), volume increases from V2 to V3, temperature increases from T2 to T3, entropy increases from S2 to S3.

Pcess 3-4: Isentropic Expansion

In this process, after heat addition, the expansion of air takes place isentropically and work is obtained from the system. The piston moves downward during this process and reaches to BDC. The pressure falls from P3 to P4, Volume increases from V3 to V4, the temperature falls from T3 to T4 and entropy remains constant (i.e. S3=S4).

Process 4-1: Constant Volume Heat Rejection

In this process, the piston rests at BDC for a moment and the cold body is brought in contact with the cylinder and the heat rejection takes place at constant volume. The pressure decreases from P4 to P1, temperature decreases from T4 to T1, entropy decreases from S4 to S1 and volume remains constant (i.e.V4 = V1).

How Diesel Cycle Implemented in 4 Stroke Diesel Engine?

This is the four working process of the diesel cycle engine that we have discussed. Now we will discuss how this cycle is implemented in the 4-stroke diesel engine. When this cycle is used in 4 4-stroke diesel engine then we have 2 extra processes. One is the suction process and the other one is the exhaust process. For heat addition diesel is used as fuel which burns and adds heat.

Let’s discuss all the process in detail

- 0-1: Suction process (Suction stroke)

- 1-2: Isentropic compression process (compression stroke)

- 2-3: Constant volume heat addition (ignition and combustion of fuel)

- 3-4: Isentropic Expansion (power stroke)

- 4-1: Constant volume heat rejection (coolant comes in contact with cylinder walls)

- 1-0: Exhaust process (Exhaust stroke)

Also Read:

Process 0-1: Suction process

In this process, the inlet valve opens and suction of air takes place at atmospheric pressure. It is called as suction stroke.

Process 1-2: Isentropic Compression

The air sucked is now compressed isentropically. Due to the compression, the temperature of the air increases to such level at which the diesel gets ignited. It is called a compression stroke.

Process 2-3: Constant Pressure Heat Addition

At the end of the compression, the piston is at TDC and at this time, the diesel fuel is injected into the cylinder through fuel injector in atomized form. As this atomized diesel fuel comes in contact with the hot compressed air, it gets ignited and combustion process starts. The combustion of fuel adds heats to the engine.

Process 3-4: Isentropic Expansion

The combustion process adds a large amount of heat and this creates a large force on the piston head and it moves downward from TDC to BDC. It is the power stroke.

Process: 4-1: Constant Volume Heat Rejection

The piston is at BDC and the coolant comes in contact with the cylinder walls and takes away heat from the engine and makes it cool. After that piston moves upward.

Process: 1-0: Exhaust Process

In this process, the piston moves from BDC to TDC and exhaust valve opens. All the burnt gases left in the cylinder escapes out through exhaust valve. It is the exhaust stroke.

This is how a four-stroke compression engine works.

Summary

Summary of Diesel cycle with operation, position of piston and changes in different parameters are given below:

| S.no | Process | Operation | Position of piston | Change in parameter |

| 1. | 1-2: Isentropic compression | Compression of air. | BDC to TDC | V: Decreases from V1 To V2T: Increases from T1 to T2P: Increases from P1 to P2S: Entropy remains constant (S1=S2) |

| 2. | 2-3: Constant Pressure heat addition | Heat is added from an external source (hot body) | At TDC for a moment and moves slightly downward. | V: Increases from V2 To V3T: Increases from T2 to T3P: Remains constant (P2 = P3)S: Increases from S2 to S3 |

| 3. | 3-4: Isentropic expansion | Expansion of air takes place due to heat addition. | TDC to BDC | V: Increases from V3 to V4T: Decreases from T3 to T4P: Decreases from P3 to P4S: Entropy remains constant (S3=S4) |

| 4. | 4-1: Constant volume heat rejection | Heat is rejected to a sink. | At BDC for a moment | V: Volume remains constant(V4 = V1 )T: Decreases form T4 to T1P: Decreases from P4 to P1S: Decreases from S4 to S1 |

Application

The diesel cycle is used where more power is needed with less amount of fuel. Mainly it is used in two stroke and 4 stroke diesel engines.

Conclusion

In this post, we have discussed what is Diesel Cycle with PV and TS Diagram. I hope you have understood it clearly and if you found this piece of information useful and valuable then don’t forget to like and share it.