Roots supercharger is the oldest among the other superchargers, roots name comes after the Roots-type blower the American inventors and brothers Philander and Francis Marion Roots, founders of the Roots Blower Company of Connersville, Indiana USA, who actually patented the basic design and idea for this. All the superchargers mean to produce more power in an internal combustion engine. Engine works by drawing a mixture of air and fuel into its cylinders, compressing that mixture, and then burning it.

It is used to pressurize the air at intake or increase the air density supplied to internal combustion engines, more air means more oxygen allowing it to burn more fuel and to get more power by increasing in air during the combustion in an engine. The more air that can be used to create a large amount of explosion to produce the more power and torque the engine produces. For that Roots supercharger is a one of its kind of supercharger like other centrifugal and twin-screw supercharger.

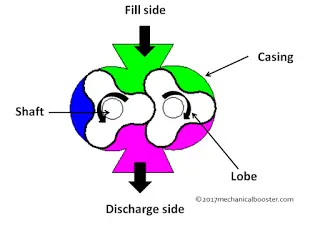

Main Parts of Roots Supercharger

The roots supercharger is constructed almost entirely of cast iron, with the exceptions of shafts, bearings, and gears. A rotor is a combination of lobes and shafts. There are two different designs available for this type of supercharger, one is straight and another is twisted lobes. The lobes are supported on anti-friction bearings by the end plates or head plates which are fixed at the front and backside of the device and surround the lobes.

Also Read:

- How Turbocharger Works – Explained?

- What is Brake Booster and How it Works?

- What is Cone Clutch and How it Works?

Let’s see each part in detail:

1. Drive pulley:

From the drive pulley, this device gets the rotational power from the engine belt. As the pulley rotates two rotors and lobes can try to move in a different direction as per mechanism. It can initiate further processes for the root supercharger.

2. Lobes:

The most important part of the root supercharger is the lobe also known as an impeller. Lobes normally are cast grey iron with cast ductile iron for greater strength. It requires corrosion or erosion resistance because continuous airflow from outside can make humidity and temperature differ as per the environment.

3. Bearings:

Which supports the lobes and anti-friction type; it may be a ball or roller. After a long use of the device, the bearing maybe wear out and cause noise problem

4. Gears:

It has helical types of gears. It must be of high quality with good tolerance to maintain clearance between two lobes of the rotor. A small inaccuracy in the gear profile makes contact with rotating lobes and also causes the noise.

5. Shafts:

Both shafts support the lobes. It has a restricted design and diameter in order to support the rotor and lobe. The shaft is usually made up of ductile iron. It has a unique characteristic that can be replaceable without changing the other components when damage is caused.

6. Casing:

The casing is the outer body of the root supercharger, which looks like the box. All parts lobes, rotors, inlet, and discharge ports are fixed and the casing is made up of cast grey iron. Another consideration is noise level, if the thicker the casing the lower the noise.

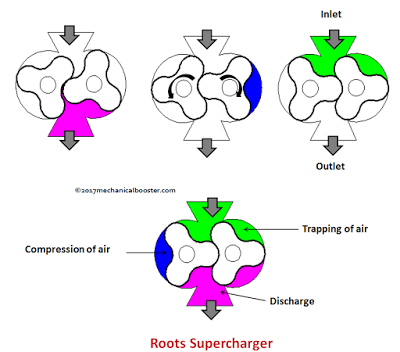

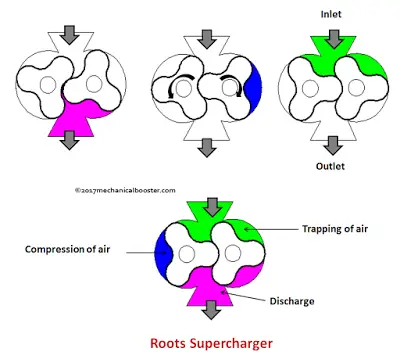

Working Principle of Roots Supercharger

It can be powered mechanically by engine belt. The roots supercharger is a positive displacement supercharger, works on a very simple principle. As the drive shaft is rotated by engine belt, the lobes turn in opposite directions with very tiny clearances between each other and between the rotors and the casing. As each lobe passes air at the inlet fill side, a measured quantity of air is trapped between the lobes and the casing. As the shafts continue to rotate, this amount of air is transported around the casing to the discharge port side and created high-pressure air directly send to inlet manifold through the intercooler and then cylinder of an engine. With this more quantity of air is used to burn more fuel and produce more power and torque in result.

Let’s discuss its working step by step.

- The air from the air filter enters into the casing of the supercharger. The left lobe rotates anti-clockwise, and the right lobe rotates clockwise.

- As the lobes rotates it traps the air in the space between the lobes and casing and compresses it.

- The compressed air is then discharged to the inlet manifold of the internal combustion engine through the intercooler. the intercooler reduces the temperature of the air and brings it to the desired value suitable for combustion.

- Both the lobes work in the same manner but the direction of their rotation is different.

For a Better Explanation Watch the Video Given Below:

Also Read:

- Difference Between Turbocharger and Supercharger

- Types of Gearbox – Complete Explanation

- What is Difference Between Petrol and Diesel Engine?

Advantages of Roots Supercharger

- It creates the instant boost at low engine rpm.

- Simple in construction and easier installation.

- Do not use engine oil.

Disadvantages of Roots Supercharger

- Create a lot of heat.

- Bulky in size.

- It only delivers a fixed amount of air per revolution.

Application:

- It is widely used in automobiles, especially in muscle and drag racing cars and hot rods

- Used in Truck, tractors, and pickup trucks.

Conclusion

In this article, we have learned about how roots supercharger works, its main parts, working principles, advantages, and disadvantages with the application. If you find anything missing or modification, please give your valuable comment. And if you get some information from this article then don’t forget to like and share it.