What is Reciprocating Pump?

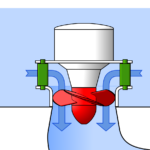

Reciprocating pump is a hydraulic machine which converts the mechanical energy into hydraulic energy. It does this work by sucking liquid into a cylinder containing a reciprocating piston which exerts a thrust force on the liquid and increases its hydraulic energy ( pressure energy of liquid). It is a type of positive displacement pump which consists of piston or plunger. Piston is present in a cylinder in which it does reciprocating motion. It is used at a place where relatively small amount of water is to be delivered at higher pressure.

Main Parts

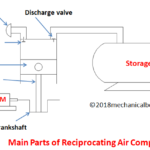

The main parts of a reciprocating pump is as follows:

1. A cylinder with piston, piston rod, connecting rod and a crank.

2. Suction pipe,

3. Delivery pipe,

4. Suction valve,

5. Delivery valve and

6. Air vessel.

Let’s discuss all these parts in detail

1. A cylinder with piston, piston rod, connecting rod and a crank

Cylinder is used to suck water and delivers it to the desired location. The piston executes reciprocating motion (back and forth motion) within the cylinder. Piston is connected to the crankshaft through connecting rod. An external power source is used to drive the piston within the cylinder. As the piston moves backward it sucks the liquid in the cylinder and when it moves forward it delivers the water from the cylinder to the required location.

2. Suction Pipe

As its name indicates, it is used to suck the water from the water reservoir to the cylinder. It connects the inlet of the pump with water tank.

3. Delivery Pipe

It is a pipe which is used to deliver the water from the cylinder to the desired location. It connects the outlet of the pump to the tank where the water is to be delivered.

4. Suction Valve

It is a valve which is present at the suction side of the pump. It opens during suction of water from the tank to the cylinder and remains closed during compression of the liquid.

5. Delivery Valve

It is a valve which is present at delivery side and opens during compression of the liquid and remains closed when the water is sucked from the water tank.

6. Air Vessels

Air vessels in the reciprocating pump is used to get uniform discharge rate. It is provided on both suction and delivery side and connected to suction and delivery pipe.

Also Read: Centrifugal Pump – Working Principle, Main Parts with Application

Types of Reciprocating Pump

It is divided on the basis of source of work and the mechanism of operation.

On the basis of source of work it is divided as

1. Simple hand operated: Bicycle pump for the tyre inflation.

2. Power operated: Deep well pump

On the basis of mechanism

1. Single Acting Reciprocating Pump: In this, only one side of the piston engages to displace the liquid. Eg : piston syringe.

2. Double Acting Reciprocating Pump: In this, both sides of the piston engages to displace the fluid. In each stroke of the piston, two process i.e. suction and discharge carried at the same time. It consists of two inflow and two outflow pipes

Working

Single Acting Reciprocating pump

During suction stroke, the piston moves backward and this opens the suction valve making the water enter into the cylinder. During suction the delivery valve remains closed and no water is discharged through it.

After suction stroke, the piston moves forward, delivery valve gets open and suction valve come into close position. As the piston moves forward it exerts thrust force on the liquid and it starts escaping out of the cylinder through delivery pipe. The water from the delivery pipes reaches to its required destination.

Also Read: All Types of Turbine That You Must Know

Double Acting Reciprocating Pump

As the piston moves to the right hand side as shown in the fig above. The following process takes place at left and right side.

At left side:

The suction valve opens and delivery valve gets closed. The water from the water reservoir is sucked into the cylinder.

At right side:

The suction valve is gets closed and delivery valve gets open. the water sucked in the previous stroke is discharges out of the cylinder.

In the same way as the piston moves to left hand side, the discharge of the liquid takes place at left side and suction takes at the right side. And in each stroke of the piston, both suction and discharge of liquid takes place at the same time. If suction is taking place at right side than discharge takes place at left and vice-versa.

Advantages

1. High pressure is obtained at the outlet.

2. Priming process is not needed in this pump.

3. It provides high suction lift.

4. It is also used for air.

Disadvantages

1. It requires high maintenance because of more wear and tear of the parts.

2. Low flow rate i.e. it discharges low amount of water.

3. They are heavy and bulky in size.

4. High initial cost.

Application

• It is used at a place where low discharge rate is required with high pressure. It is mostly used to deliver water at large heights such as in deep well.

• It is used for inflation of tyres of bicycles.