What is a Spark Plug?

Spark Plug is a device that is used to ignite the air-fuel mixture in the engine cylinder of an internal combustion engine. They are generally used in petrol engines or engine that runs on Natural gas. For the combustion of the fuel, we need a spark to initiate the combustion process in a gasoline engine (Petrol engine). A good spark plug produces sparks at the correct timing making the combustion of air-fuel mixture efficient and this improves the working of our vehicle.

Requirements of a Good Spark Plug

- It must be reliable at high voltage transmission i.e. up to 40,000 V.

- It must have good insulation capability even at temperatures of 1000 degree Celsius, and prevent arcing and flashover.

- It must possess resistance to thermal shock (Hot exhaust gases-cold intake mixtures)

- It must make pressure-tight and gas-tight sealing with the combustion chamber.

- It must be capable to resist oscillating pressures up to approx. 100 bar.

- It should have high mechanical strength for reliable installation.

- It must have good thermal conduction by insulator tip and electrodes.

- It must possess resistance to spark erosion, combustion gases and residues.

- It must be capable of preventing of build-up of deposits on the insulator.

They are made with high-quality materials to meet the above requirements. To know about the symptoms of a bad spark plug visit the link below:

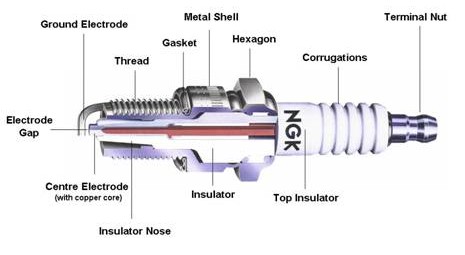

Parts of a Spark Plug

The main parts of a spark plug and its functions are

1. Plug Terminal:

It is the portion that is connected to the high-tension cable coming from the distributor cap. It conducts the high voltage to the central electrode.

2. Ceramic Insulator:

It is made up of Aluminum oxide ceramic and acts as an insulator. It separates the central electrode from the earth at up to 40,000 Volts. It can be manufactured in plain form or with profiles to prevent flashover.

3. Metal Body:

It is a steel shell manufactured with precision rolled threads for a secure fit, and easy installation and removal. It provides electrical ground to the cylinder head and helps to cool the plug by transferring heat to the cylinder head.

4. Central Electrode:

It is made nickel-based alloys consist of a copper core enclosed in it. Depending upon the type, the central electrode can be platinum or iridium. The high voltage is applied to the central electrode from the secondary winding through the distributor.

5. Ground Electrode:

It is welded to the metal body of the SP. It makes a spark path with the central electrode. It is made up of nickel-based alloys ( or iridium or titanium reinforcement)

6. Sealing washer/ Gasket:

It makes sealing with the cylinder head and helps in heat dissipation.

7. Insulator tip:

It is extended into the combustion chamber. It has a greater influence on the thermal rating of the spark plug

8. Electrode Gap:

It is the distance between the central electrode and the ground electrode. The electrode has a crucial role in spark generation. If an appropriate gap is not provided to the plug then it cannot produce a sufficient spark to ignite the fuel and may lead to a misfire.

Also Read:

- How Magneto Ignition System Works

- How Electronic Ignition System Works?

- How Battery Ignition System Works?

Types of Spark Plug

On the basis of the relative operating temperature range of the tip of the high-tension electrode, it is divided into two types.

1. Hot Spark Plug:

It has a long heat transfer path and a large area exposed to combustion gases.

2. Cold Spark plug:

It has a short heat transfer path and a small area exposed to the combustion gasses.

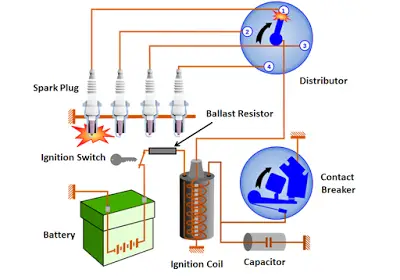

Working of a Spark Plug

- When a high-voltage current from the distributor passes to the spark plug.

- The central electrode and ground electrode are applied to a very high voltage of up to 40,000 V.

- Due to this high voltage difference between the central electrode and ground electrode, the air in between the electrode gap gets ionized.

- The ionized gas becomes a conductor and conducts current from the central electrode to the ground electrode producing spark.

- The spark produced is used to ignite the air-fuel mixture in the engine cylinder.

For a better explanation of the working of the spark plug watch the video given below:

Application of Spark Plug

It is used in all engines that work with petrol and natural gases. for example scooters, motorcycles, cars, etc. where the petrol is burnt with the help of a spark plug.