What is a Battery Ignition System?

Battery Ignition System is used in automobiles to produce a spark in the spark plug for the combustion of fuel in the I.C. engine. Here, the main source of spark generation is the battery. It is mostly used in light commercial vehicles. Almost in every petrol engine, the spark is required to burn the fuel in the Engine. Thus an ignition system is always there in petrol or gasoline engines for spark generation. There are different ignition systems such as a magneto ignition system, distributorless ignition system, and electronic ignition system. Here we will discuss one of the ignition systems. So let’s get started.

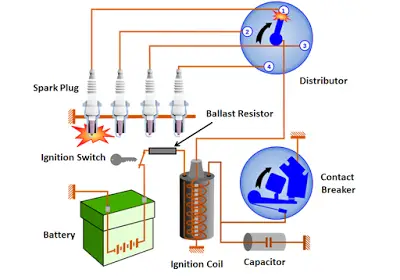

Main Parts of Battery Ignition

The main parts of the battery ignition system are

1. Battery

2. Ignition switch

3. Ballast resistor

4. Ignition coil

5. Contact breaker

6. Capacitor

7. Distributor

8. Spark plug

Let’s discuss the function of each component in detail:

1. Battery

It is a device that provides electrical energy for the ignition. The battery is charged by a dynamo driven by the engine. Generally, two types of batteries are used in spark ignition engine, lead-acid batteries & alkaline batteries. The lead-acid battery is used in light-duty commercial vehicles whereas the alkaline battery is used in heavy-duty commercial vehicles.

2. Ignition Switch

It is a switch that is used to ON or OFF the ignition system. One end of the ignition switch is connected to the battery and the other to the primary winding through a ballast resistor.

3. Ballast Resistor

It is connected in series with the primary winding. It is present between the ignition switch and the ignition coil. The function of the ballast resistor is to prevent the overheating of the primary winding of the ignition coil. How it does do this? The Ballast Resistor is made of iron wire and iron wire has the property that its electrical resistance increases rapidly with a small increase in temperature. If the current from the primary winding flows continuously, the temperature of the ballast resistor increases and this increases the electrical resistance and reduces the flow of electric current through the primary winding. The reduction of current by the ballast resistor prevents the overheating of the primary winding.

Also Read:

- How to Fix an Ignition Key That Doesn’t Turn

- What is Check Engine Light Symbol and Meaning?

- Car Dashboard Symbols And Meanings (Complete Guide)

4. Ignition Coil

It is used to produce high voltage sufficient to generate a spark across the electrodes of the spark plug. It acts as a step-up transformer and converts a 6 or 12-V of the battery into a very high voltage of about 15,000 to 30,000 V.

It consists of a soft iron core surrounded by two insulated coils, named primary winding and secondary winding. The primary winding consists of 200-300 turns of 20 gauge wires capable of producing a resistance of 1.15 ohm. The secondary winding consists of 21,000 turns of 38-40 gauge enameled wire and it is sufficiently insulated to withstand high voltage.

One end of the primary winding is connected to the battery terminal through the ballast resistor and ignition switch. And another end is connected with the contact breaker as well as the secondary winding. In the case of secondary winding, it’s one end is connected to the central high-tension terminal of the distributor. And another end is connected with the primary winding.

5. Contact Breaker

It is a mechanical device that is used for making and breaking the primary circuit of the ignition coil.

It has two metal points made up of tungsten and placed against each other. These metal points have a circular flat face of about 3 mm in diameter. Among the two metal points, one is fixed, and the other is moveable. The fixed contact point is earthed by mounting it on the base of the contact breaker assembly. The movable contact point is attached to the spring-loaded pivoted arm which is electrically insulated.

The pivoted arm generally has a heel or rounded part (cam follower) made up of some plastic material and attached in the middle of the arm. The heel is rest on the cam driven by the engine. Every time when the cam passes under the heel, the contact points are forced apart and the circuit is broken. The pivoted arm is spring-loaded and in the case when the points are not separated by the cams, it is held together by the spring force and closes the primary circuit. When the points are closed, the current flows through the primary circuit and it stops if open.

6. Capacitor

The capacitor used in the ignition system is similar to the electrical capacitor. The capacitor is an electrical device in which two metal plates are separated from each other through insulating materials (air).

It is connected in parallel with the contact breaker. It prevents the contact points of the contact breaker from being damaged. If there is no condenser or capacitor used in the primary circuit, the high primary voltage caused by the collapse of the magnetic field around the primary winding would cause an arc across the breaker points. The arc produced would burn and destroy the points and would also prevent the rapid drop in the primary current and magnetic field which is necessary for the generation of the high secondary voltage.

7. Distributor

It is a device used in the Battery Ignition System to distribute the ignition pulses (surges) to the individual spark plug in a correct sequence and at the correct instant of time.

There are two types of distributor

1. Brush Type: In the brush-type distributor, it contains a carbon brush carried by the rotor arm that slides over the metallic segments embedded in the distributor cap.

2. Gap type: In this type of distributor the rotor arm passes very close to the segments of the distributor cap but does not touch it.

It also contains some other auxiliary units. In the lower part of the housing, it has a speed-sensitive device or governor whose main function is to advance the spark with the increase in the engine speed. A contact breaker assembly is present above this, which can be rotated to adjust the timing of the spark.

In the upper part of the housing, a high-tension distributor is located. It also carries the vacuum ignition governor which serves to retard the spark as the load on the engine increases. Each metallic segment of the distributor is connected to each spark plug.

As the rotor rotates, the contact point opens; this allows the high-tension current to pass to the spark plug through the segments to which the spark plug is connected. The sequence in which the spark plug is connected to the distributor cap depends upon the firing order of the engine.

8. Spark Plug

The spark plug is used to generate sparks to ignite the air-fuel mixture in the combustion chamber. Each spark plug is connected to the distributor of the ignition system.

Working Of Battery Ignition System

- In the Battery ignition system, as the ignition switch is ON, the current from the battery starts to flow through the primary circuit through the ballast register, primary winding, and contact breaker.

- The current flowing through the primary winding induces magnetic field around it. The more will be the current, the stronger will its magnetic field.

- As the contact breaker opens, the current through the primary winding collapse and this immediate collapse in the current induces a voltage of about 300V in the primary winding. This voltage induced in the winding charges the capacitor to a much greater voltage than the battery. As the capacitor charged, the current through the primary winding stops, and the current starts to flow to the battery from the capacitor. This reverses the direction of the current and magnetic field in the primary winding. Due to the collapsing and reversing of the current and magnetic field, a very high voltage of about 15,000 to 30,000 V is induced in the secondary winding.

- The high voltage current induced in the secondary winding is transferred to the distributor through a high tension cable.

- The distributor has a rotor that rotates inside the distributor cap. The distributor cap has metallic segments embedded into it. As the rotor rotates, it presses and opens the contact breaker point. This allows the high tension current to transfer to the spark plugs through the metallic segments.

- As the high tension current reaches the spark Plug, it produces a spark in the engine cylinder for the combustion of the air-fuel mixture.

Advantages of Battery Ignition

- It provides a good spark at low engine speed.

- Low maintenance cost.

Disadvantages of Battery Ignition

- In the battery ignition system, the battery is necessary for the ignition. It becomes difficult to start the engine when the battery is discharged.

- Occupies large space

- The efficiency of the system decreases as the engine speed increases.

- Since the breaker contact points are continuously subjected to mechanical as well as electrical wear which results in short maintenance intervals.

Application of Battery Ignition

The Battery Ignition system is used in light commercial vehicles such as cars, buses, motorcycles, etc.

Conclusion

Here we have discussed the battery ignition system, its main parts, working, advantages, disadvantages, and applications. I hope you understand everything about it. And If you have any doubt related to that you can ask through your valuable comments. And If you find this piece of information valuable and useful then don’t forget to like and share it.