The engine is the device that is used to convert the chemical energy of the fuel into mechanical energy. All the vehicles that are running on the roads either have two-stroke or four-stroke engine. since we have different types of engines but Here in this article, we will discuss only two stroke engines. The topics that we will cover in this topic are definition, construction, working, advantages and disadvantages, and application.

What is a Two Stroke Engine?

The two-stroke engine is a reciprocating engine in which the piston does reciprocating motion (two-time movement) ( i.e. from TDC to BDC and BDC to TDC ) to produce a power stroke. Two-stroke engines are mainly used in two-wheeler vehicles like motorcycles. Compared with four four-stroke engines, the two-stroke engine produces more power.

What is a Stroke?

When the piston moves from TDC to BDC or BDC to TDC then this movement of the piston from TDC to BDC and vice versa is called one stroke. let us understand it more clearly.

- The movement of the piston from TDC to BDC is called as one stroke.

- When the piston moves from BDC to TDC it is also called as one stroke of the engine.

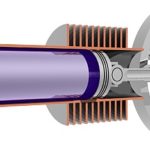

Construction of 2 Stoke Engine

If you start looking from the top of the engine then you will see a spark plug at the top and as we move downward we see the combustion chamber, exhaust port, piston, transfer port, intake port, connecting rod, and crankcase.

Main Components

1. Spark plug:

The spark plug is a device that is used to generate spark within the cylinder. The spark produced is used to burn the fuel in the cylinder.

2. Piston:

The piston is the reciprocating part of the engine. It is used for the suction and compression of the fuel within the cylinder.

3. Cylinder:

It is that part of the two stroke engine which holds piston within it. The inlet and exhaust ports are present in the cylinder. Cylinder head consist of the combustion chamber and the spark plug.

4. Transfer Port:

It is used to transfer the compressed fuel from crankcase to the cylinder.

5. Connecting Rod:

It connects the piston and crankshaft. It transfers the power from the piston to the crankshaft.

6. Crankcase:

It acts as the base of the engine. It supports the crankshaft and camshaft in suitable bearings and provides the arms for supporting the engine on the frame.

7. Crankshaft:

It is that part of the engine that is used to convert the reciprocating motion of the engine into the rotating motion with the help of a connecting rod.

8. Exhaust Port:

It is used to transfer the burnt gases out of the engine after the completion of the power stroke.

9. Inlet Port:

The fresh charge enters into the cylinder through the inlet port.

10. Balancing Weight:

It is the weight used for the balancing of the engine. The balancing weight is present in the crankshaft.

Also Read:

- Valve Timing Diagram of Two Stroke and Four Stroke Engine

- What is Four Stroke Engine?

- Difference Between 2 Stroke and 4 Stroke Engines

Working of Two Stroke Engine

- In two-stroke engine, the suction and exhaust strokes are eliminated.

- There are only two remaining strokes – these are the compression stroke and Expansion or power stroke and usually called as upward stroke and downward stroke.

- Instead of valves, the two stroke engine consists of inlet and exhaust ports.

- The fresh charge enters into the cylinder through the inlet port and burnt gases escape out through the exhaust port.

- The burnt exhaust gases are forced out through the exhaust port by fresh charge which enters the cylinder nearly at the end of the working stroke through the inlet port.

For a better understanding of the working of 2 stroke engine watch the video:

The two strokes of a two-stroke engine are described as follows:

1. Upward stroke:

- During upward stroke, the piston moves from BDC to TDC and compresses the charge (air-fuel mixture) in the combustion chamber of the cylinder.

- Because of the upward movement of the piston, a partial vacuum is created in the crankcase and this allows the entry of the fresh charge into the crankcase through the uncovered inlet port.

- The exhaust port and the inlet port remains covered when the piston at the TDC.

- The ignition of the fresh charge is takes place by the spark plug.

2. Downward stroke:

- As soon as the combustion of the fresh charge takes place, a large amount of the hot gases is produced which exerts a very high-pressure force on the top of the piston. Due to this high-pressure force, the piston moves downward and rotates the crankshaft and does useful work.

- During this stroke the inlet port is covered by the piston and the new charge is compressed in the crankcase.

- Further downward movement of the piston uncovers first the exhaust port and the transfer port and the exhaust starts through the exhaust port.

- As soon as the transfer port opens, the charge through it is forced into the cylinder.

- The charge strikes the deflector on the piston crown, rises to the top of the cylinder and pushes out most of the exhaust gases.

- The piston is now at the BDC position. The cylinder is completely filled with the fresh charge but it is somewhat diluted with the exhaust gases.

- Finally, the cycle event is then repeated. We get two strokes for the single revolution of the crankshaft.

Port Timing diagram for a two-stroke cycle engine

Advantages of 2-Stroke Engine

- Two stroke engine gives a working stroke for each revolution of the crankshaft. The four stroke engine gives a working stroke for each two revolutions of the crankshaft.

- Power developed by the two-stroke engine is twice that developed by the four-stroke engine for the same engine speed and volume.

- Lighter flywheel is required in two stroke engine because of the more turning moment on the crankshaft.

- For the same power, a two stroke engine is more compact, light and requires less space than a four stroke engine, therefore is used in motorcycles and scooters.

- It is simpler in construction and mechanism.

- There is no valve and valve mechanism in it. The ports can be easily designed and covered and uncovered by the movement of the piston itself.

- It has high mechanical efficiency.

- It requires fewer spare parts due to its simple design.

Disadvantages

- It has high fuel consumption.

- Thermal efficiency is less than four stroke engine.

- The charge is diluted by the burnt gases due to incomplete scavenging.

- It produces greater noise.

- It does more consumption of the lubricating oil.

- There is a greater wear and tear of moving parts.

Application

- It is used in lightweight vehicles like scooters, motorcycles, mopeds, etc which use gasoline as fuel.

- It is also used in many diesel engines, mainly industrial and marine engines, as well as in some heavy trucks and machinery.

If you found this piece of information useful then don’t forget to like and share it.