You might have heard about the Brinell hardness test in some books. But do you know the meaning as well as the purpose of this test. If no then, keep reading this post because in this article you will get to know all the details about the test. So, let us start our discussion.

As per the name, the Brinell hardness test is used to determine the hardness of the given material and this hardness test is in use for many years. As per its definition, a small metal ball acts as the indenter and a force is applied on the ball to produce the given indentation. The ball is placed on the metal workpiece.

History Behind the Brinell Test

Let’s take a quick glance at the history behind the Brinell test. In 1900, Dr. J.A. Brinell invented this test. As an honor to him, the test named as a Brinell test. It is the oldest hardness test of all time. This test is used to calculate the hardness of the castings and forgings.

In the USA, this test is done particularly for iron and steel castings. A force of 3000 Kgf and a small carbide ball of 10 mm diameter is considered. For determining the hardness of the softer alloys, a force of 500 Kgf is considered and carbide balls of 5mm or 10mm diameter are considered.

Baby Brinell Test

Have you heard about the “Baby Brinell test”? The word “Baby Brinell test” sounds funny right? Well, though it looks like the funny word and it has its own significance. So, what is this Baby Brinell test? In Europe, the Brinell hardness test is often used for small applications. And small forces of almost 1 Kgf are considered and the balls of 1 mm diameter are used. So, as small parameters are considered during this test in Europe, so, this test is called the “Baby Brinell test” in Europe during the small applications.

Exact Procedure of Brinell Hardness Test:

You might be thinking about which type of indenter is used in this test? Almost in all applications, while carrying out this test, carbide balls are used as an indenter.

- Step 1: The indenter is placed on the given material and a force is applied to the indenter.

- Step 2: Now, this force is applied for 10-15 seconds.

- Step 3: Then, the indenter is removed after the above mentioned 10-15 seconds. A small circular indent will be formed on the surface of the given material on which the indenter ball was being kept.

- Step 4: Generally, the size of the indent is measured by using the microscope and suitable measuring devices.

Also Read:

- What is Induction Heating?

- What is Annealing Process and Why it is done?

- 37 Types of Hammers that You Don’t Know?

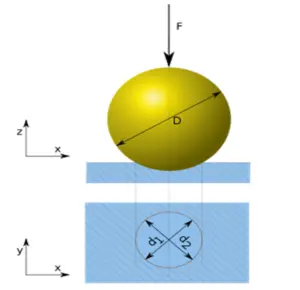

For a better understanding of the procedure of the Brinell hardness test, see the below image carefully.

By considering the above image, see that the force is applied on the carbide ball indenter. Here, D is the diameter of the Carbide ball while d is the diameter of the indentation.

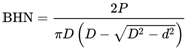

BHN = Force Applied/ surface area of the indentation on the metal workpiece.

The Brinell Hardness Number is used to convey the hardness of the given material. This Brinell Hardness Number is termed as the BHN and it is the function of the force applied divided by the surface area of the indentation made by the ball on the given material. The units of the BHN are kgf/mm2. If the BHN number is multiplied by the acceleration due to gravity then, the BHN number is expressed in the Megapascals.

In many places, the BHN is also called as the HB. For better understanding, see the below example.

Suppose, if hardness is expressed in the form, “HBW 10/3000”. Now, here the HBW indicates the tungsten carbide while 10 indicates the diameter of the carbide ball and 3000 indicates the force in the kilograms force (in kgf). If suppose, instead of the tungsten carbide ball, steel ball is used then, the hardness is expressed as

“HBS 10/3000”. Here, HBS indicates the use of the steel balls.

Sometimes, the hardness is also expressed in the form

![]()

Here,

![]() is the force applied in the units kgf while the YY indicates the type of material on which the force is applied.

is the force applied in the units kgf while the YY indicates the type of material on which the force is applied.

Let’s take the hardness expressed in the form: 250 HB 30D2. It indicates the force of 250 kgf is applied on the steel material.

The values of the YY are for different material as follows:

| Material | Value of YY |

| Steel | 30 |

| Aluminium alloys | 5 |

| Copper alloys | 10 |

See the below table for the hardness of different materials:

| Material | Hardness |

| Softwood | 1.6 HBS 10/100 |

| Lead | 5 HB |

| Copper | 35 HB |

| Pure Aluminium | 15 HB |

| Hardwood | 2.6 to 7 HBS 10/100 |

| Mild Steel | 120 HB |

| Hardox wear plate | 400-700 HB |

| Glass | 1550 HB |

| Rhenium Diboride | 4600 HB |

For Better Explanation about the Brinell Hardness Test Watch the Video given Below:

Advantages

- The most important benefit of this test is that it can be used for determining a large variety of materials.

- It is easy to carry out and a simple set-up is required to carry out this test.

- It gives you the exact value of the hardness.

- This test is the most perfect for finding the hardness of the heterogeneous materials.

- As it is the simplest hardness determining test, not too much time is required to complete this test.

Disadvantage

- The downside of this test is that you have to measure the size of the indent carefully. Error in calculating the size of the indent leads to the error in the value of the hardness number. You may find the parallax error.

- This test is suitable for the flat surfaces of the given material. If the material surface is not flat then, it is very difficult to carry out this process.

In today’s article, we explained to you all the information about the Brinell hardness test, formula, the importance of the Brinell hardness number and the advantages as well as disadvantages of this test. If you like our explanation then, please take a second to share this article!