What is EDM (Electrical Discharge Machining)?

Electrical Discharge Machining (EDM) is a non traditional machining and electro thermal process in which material from the workpiece is removed by using electrical discharges (sparks).

- It was first observed in 1770 by Joseph Priestley. He was an English physicist.

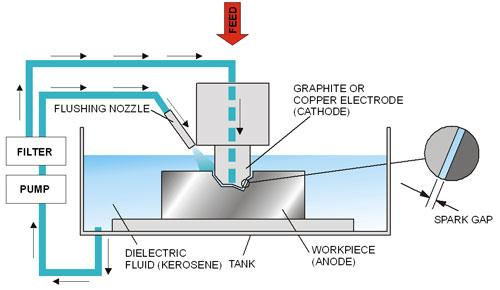

- In an EDM machine, the material is removed by rapidly recurring (repeating) discharges of current in between the electrodes. The electrodes are separated by a dielectric liquid and a high voltage is applied across them.

- It is used to machine those materials which are difficult to machine and have high strength temperature resistance.

- EDM can be used to machine only electrically conductive materials. Otherwise, it cannot be used.

- One of the electrodes is called a tool and the other is called as a workpiece. Here the tool is connected to the negative terminal of the power supply and the workpiece is connected to the positive terminal.

Working Principle of EDM

In Electrical discharge machining; a potential difference is applied across the tool and w/p in pulse form. The tool and workpiece must be electrically conductive and a small gap is maintained between them. The tool and workpiece are immersed in a dielectric medium (kerosene or deionized water).

As the potential difference is applied, electrons from the tool start to move towards the workpiece. Here the tool is negative and w/p is positive. The electrons moving from the tool to the w/p collide with the molecules of dielectric medium.

Due to the collision of electrons with the molecule, it gets converted into ions. This increases the concentration of electrons and ions in the gap between the tool and w/p. The electron moves towards the w/p and ions towards the tool.

An electric current is set up in between the tool and w/p and is called plasma. As the electrons and ions strike the w/p and tool, its kinetic energy changes to heat energy. The temperature of the heat produced is about 10,000 degree Celsius. This heat vaporizes and melts the material from the workpiece. As voltage is break down, the current stops flowing between the tool and w/p. And the molten material in the w/p is flushed by circulating dielectric medium leaving behind a crater.

The spark generation is not continuous because the constant voltage is not applied across the electrodes. The voltage is applied in pulse form.

Also Read:

- How Electron Beam Machining Process Works?

- What is Water Jet Machining Process and How it Works?

- Laser Beam Machining – Main Parts, Principle, Working with Application

Types of Electrical Discharge Machine

There are two types of EDM machine

(i) Ram/Sinker EDM :

This EDM machine consists of a tool and workpiece immersed in a dielectric medium. It consists of ram type of tool and it may be created according to the shape or form required to produce the workpiece. It is also called cavity type or volume EDM.

(ii) Wire EDM:

In wire EDM, thin single-strand wire is used to cut the material from the workpiece. The wire is usually made of brass. A constant gap is always maintain between the wire and w/p. The wire is continuously fed through the workpiece submerged in a tank with dielectric medium. Here spark is generated in the gap between the wire and workpiece. It is used to cut metal as thick as 300 mm and to make punches, dies, and tools from hard metals that are difficult to cut from other methods.

Equipment used in EDM

The various equipment used in Electrical Discharge Machining are:

1. Dielectric Reservoir, Pump, and Circulating system

A pump is used to circulate the dielectric medium between the two electrodes ( tool and workpiece). Kerosene or deionized water is used as a dielectric medium.

2. Power Generator and Control Unit

A generator is used to apply potential differences. The voltage used in this machining process is not constant but it is applied in pulse form. A control unit is used to control the different operations during the machining process.

3. Working Tank with Work Holding Devices

It has a working tank with a work-holding device. The workpiece is held in the work holding devices. The tank contains a dielectric medium.

4. Tool Holder

5. Servo System to Move the Tool

A servo system is used to control the tool. It maintains the necessary gap between the electrodes ( tool and workpiece).

Working of Electrical Discharge Machining (EDM)

- In EDM, first, the tool and w/p are clamped to the machine. After that, with the help of a servo mechanism a small gap (of a human hair) is maintained between the tool and the workpiece.

- The tool and workpiece are immersed in a dielectric medium (kerosene of deionised water).

- A potential difference is applied across the Electrode. An electric spark is generated between the tool and the workpiece. This spark generates a heat of about 10,000 degree Celsius. And due to this heat, the material from the workpiece starts to vaporize and melts.

- The spark generation in electrical discharge machining is not continuous. As the voltage breaks, the dielectric fluid flushes away the molten materials leaving behind a crater.

- This process keeps continuing and machining the workpiece.

For a Better Explanation of the Electrical Discharge Machining Process Watch the Video:

Advantages Of EDM

- It can be used to machine any material that is electrically conductive.

- It can easily machine thin fragile sections such as webs or fins without deforming the part.

- Complex dies sections and molds are produced accurately, faster, and at a lower price.

- It is a burr-free process.

- It does not involve contact between the tool and the workpiece. So delicate sections and work materials can be machined easily without any distortion.

- It can machine complex shapes which are not manufactured by conventional machine tools.

- It can produce tapered holes.

Disadvantages of EDM

- It can machine only electrically conductive materials.

- Low rate of metal removal.

- More tool wear during machining.

- Takes extra cost and time for the preparing electrodes for ram/sinker EDM.

- High power consumption.

- Overcut is formed in EDM.

Application of EDM

- It is mostly used by mold-making and dies industries.

- It is used in prototype manufacturing in the aerospace, automobile, and electronic industries.

- It is used for coinage die-making.

- It is used to create small holes in a variety of applications.

- It is used to disintegrate parts that cannot disintegrate easily such as broken tools (studs, bolts drill bit, and taps) from the workpiece.